|

| |

TM 5-4320-305-24

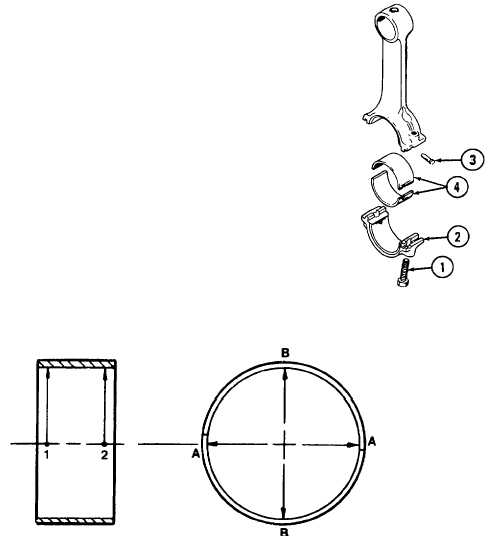

4-11. REPLACE/REPAIR CONNECTING ROD ASSEMBLY (Continued)

13

Remove big-end bolts (1), bearing cap (2), and dowel pin (3), and

carefully insert bearing shells (4). Reinsert pin and tighten big-

end bolts following procedure described in step 9 above.

14

Check bearing shell bore.

a.

Measure with inside micrometer at points 1 and 2 and along axes A and B. Measurement should be 2.5209 to

2.5224 inches (64.031 to 64.069 mm).

b.

If any measurement is outside the tolerance limits, replace the bearing shells.

c.

Make sure that measurements at points 1 and 2 are not different nor outside the tolerance limits indicating

that bearing shell is wearing in a conical shape.

d.

Make sure measurements along axes A and B are not different nor outside the tolerance limits indicating

bearing shell is wearing in an oval shape.

e.

If bearing shell is wearing out-of-round, replace it and check the crankpin on the crankshaft. Follow procedure

described in paragraph 4-12. Also check pistons and cylinders for unusual wear. Follow procedures

described in paragraphs 4-9 and 4-10.

4-87

|