|

| |

TM 5-4320-305-24

4-10. REPLACE/REPAIR PISTON ASSEMBLY (Continued)

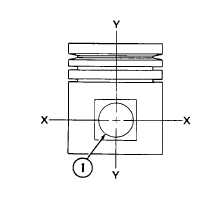

7 Measure piston pin bore (1) on X and Y axis with precision bore

gage. Measurement should be 1.3780 to 1.3782 inches (35.00 to

35.006 mm). If bore measurement is larger than 1.3782 inches

(35.006 mm) or is out-of-round, replace piston. This is also an

indication of unusual wear. Check cylinder in accordance with

paragraph 4-9 and also connecting rod in accordance with

paragraph 4-11.

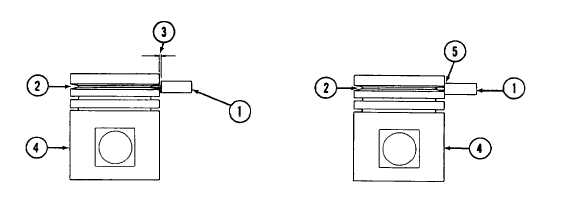

8 Measure axial clearance of trapezoidal ring groove with piston ring groove gage No. 130360 (1). Insert gage into ring

groove (2). If a gap (3) exists between the inserted gage and piston (4), the axial ring clearance is 0.1096 to 0.1104

inch (2.784 to 2.804 mm) and the piston is still usable. Do not replace piston. If the gage contacts the side of the

piston with no gap (5), the axial ring clearance is too great and the piston must be replaced.

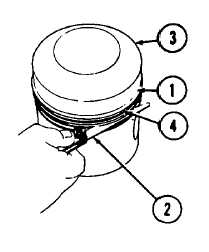

9 Measure axial ring clearance of taper ring groove (1) with

standard clearance gage (2). Measurement should be

0.102 to 0.1028 inch (2.59 to 2.61 mm). If measurement

is greater than 0.1028 inch (2.61 mm), replace piston (3).

10 Measure axial ring clearance of oil control ring groove (4) with

standard clearance gage (2). Measurement should be 0.1980

to 0.1988 inch (5.03 to 5.05 mm). If measurement is greater

than 0.1988 inch (5.05 mm), replace piston (3).

4-75

|