|

| |

TM 5-4320-305-24

4-9. REPLACE/REPAIR CYLINDER ASSEMBLY (Continued)

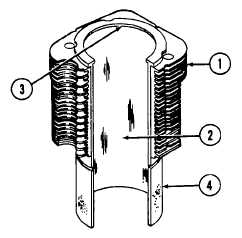

2 Clean cylinder (1) thoroughly with dry cleaning solvent. Dry with compressed air. Inspect for damage, warpage, rust, or

corrosion. If severely damaged or warped, replace complete with new piston as necessary.

3 Inspect cylinder for cracks, scoring, glazing (2), a ridge (3) on the upper portion of inner surface, or adhering metal

particles (fretting) (4) on outer surface.

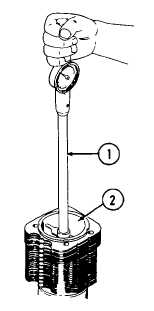

4 Set precision bore gage (1) in cylinder bore (2), and measure bore diameter. Diameter should be 3.9370 to 3.9457

inches (100.0 to 100.22 mm).

4-66

|