|

| |

TM 5-4320-305-24

4-4. REPAIR INJECTION PUMP (Continued)

79 Remove clevis (116) and shaft (117) as an assembly.

80 Remove threaded bushing (118).

81 Disassemble clevis (116) by removing spring-loaded retainer (119), compression springs (120, 121, and 122), and

spring capsule (123).

82 Slide shaft (117) from clevis (116).

83 Remove sliding pad (124) from clevis (116).

84 Remove nut (125) and threaded pin (126).

85 Remove two bolts (127) and two washers (128).

86 Remove bracket (129) and two washers (130).

87 Remove bolt (131).

88 Remove lockwasher (132) and washer (133).

89 Remove control lever (134).

90 Remove washers (135 and 136).

91 Remove C-clip (137). Remove bearing bushing (138) and washer (139).

92 Remove capsule (140).

93 Remove C-clip (141). Remove bearing bushing (142) and washer (143).

94 Remove screw plug (144).

95 Remove lever (145). Remove screw (146) from lever.

REPAIR:

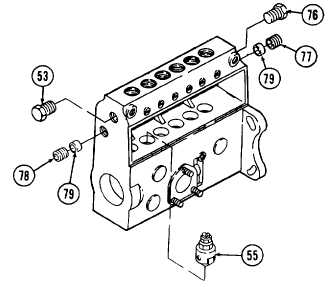

1 Inspect injection pump housing for cracks, distortion, or

thread damage. Clean up rough barrel seats in

housing using light cuts with barrel seat cutter KDEP

2995. If other defects are found, replace housing

along with screw plug (53), screw plug (76), guide

bushing (77), threaded ring (78), and two rings (79) as

an assembly.

2 Inspect six roller tappet assemblies (55) by rotating

roller and checking that it turns smoothly without

wobble. Also check for flat spots, pitting, scratches, or

cracks. If defects are found, repair as follows:

4-15

|