|

| |

TM 5-4320-305-24

3-9.

REPLACE/REPAIR COOLING AIR BLOWER AND COOLING AIR DUCTING (Continued)

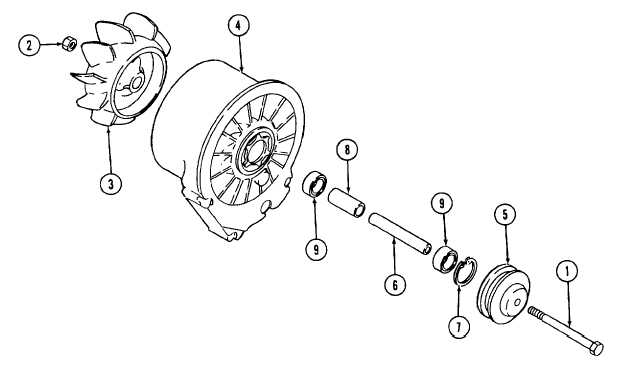

8

Check blades of bottom roller for indications that roller has been rubbing on blower jacket. Physical damage to

roller blades could indicate damaged blower jacket or bent quill shaft. Check surface of roller and inside diameter of

the bore into which the quill shaft is installed for corrosion or damage. Remove corrosion using emery cloth or

crocus cloth. Replace damaged bottom roller.

9

Check area of blower jacket into which the bottom roller is installed for physical damage or corrosion that would

indicate roller is rubbing jacket during operation.

10

Check inside diameter of blower jacket for corrosion or damage that would prevent reuse. Check inside diameter for

discoloration caused by overheated bearings. Check circlip groove for damage that would prevent proper seating of

circlip during installation. Replace damaged blower jacket.

ASSEMBLY:

1

If bushing (8) was removed from quill shaft (6), press quill shaft into bushing.

2

Pack ball bearings (9) with grease. Press onto quill shaft (6). Seat against bushing (8).

3-46

|