|

| |

TM 5-4320-305-24

3-4.

REPLACE/REPAIR PUMP ASSEMBLY (Continued)

3

Inspect impeller for cracks, rust, corrosion, or excessive wear. If severely damaged, cracked, or worn, replace

impeller.

4

Inspect seal housing, shaft sleeve, and flexible coupling for cracks, rust, corrosion, or other damage. Inspect mounting

surfaces. Make sure they are smooth and flat. Inspect for excessive wear where shaft sleeve contacts seal plate.

Replace damaged, cracked, or excessively worn parts.

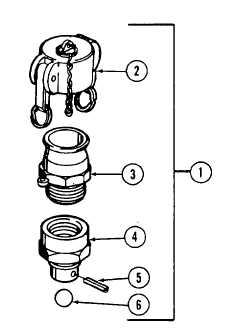

5

Inspect priming valve parts for cracks, rust, corrosion, stripped threads, or excessive wear. Be sure check valve ball

seats properly in check valve. Check that chain is securely attached to cap and coupling half. Replace priming valve

parts that are severely damaged, cracked, or worn.

REPAIR:

Repair minor nicks or burrs on pump body or seal housing and/or smooth out mounting surfaces with crocus abrasive

cloth. Clean interior or mounting surfaces. Clean and refinish outside surfaces. Remove only a minimal amount of

surface material; replace parts if necessary.

ASSEMBLY:

1

Assemble priming valve (1).

a.

Install check valve ball (6) in check valve (4) with spring pin (5).

b.

Install coupling half (3) in check valve (4).

c.

Clamp dust cap and chain (2) securely onto coupling half (3).

2

Install assembled priming valve (1) in pump body.

3-12

|