|

| |

TM 5-4320-305-10

Table 2-2. Preventive Maintenance Checks and Services - Continued

B - Before Operation

D - During Operation

A - After Operation

W - Weekly

INTERVAL

ITEM TO BE INSPECTED

ITEM

PROCEDURE

Equipment is Not

NO

B

D

A

W

Ready/Available If:

19

•

Discharge Manifold Assembly.

There is evidence

of Class 111 leaks.

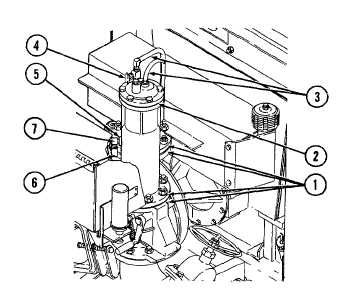

Inspect the discharge manifold for leaks at flanges (1), air

cover gasket (2), hoses (3), valve (4), discharge gage tap

(5), hose (6), and victaulic hoseline connection (7).

20

•

•

Pump Assembly.

Pump assembly

or bearing housing

Check that pump assembly (1) is securely mounted to

mounting

trailer frame (2) and engine flywheel housing (3). Check

hardware is loose

that pump body (4) and bearing housing (5) are securely

or broken. There

fastened together.

is evidence of

Class III leaks or

Check that all nuts and lockwashers (6) are tight and free

there are cracks.

of damage and corrosion.

Check that plugs (7) are securely installed in the pump

body.

Check pump body (4) for cracks at mounting feet (8),

suction and discharge flanges (9 and 10), priming check

valve port (11), and bearing housing mounting bolts (12).

2-33

|