|

| |

TM 5-4320-304-14

TM 08922A-14/1

REPAIR:

6-2. REPAIR CYLINDER HEAD AND VALVE ASSEMBLY (Continued)

3

4

5

6

7

8

9

10

11

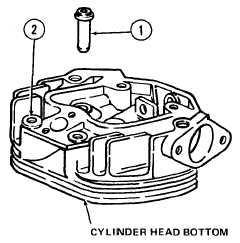

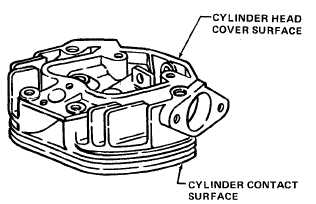

Replace cylinder head if any of the

following conditions exist: if the cyl-

inder contact surface is roughened, not

level, and cannot be repaired; if the

valve seats are so worn that recutting

is no longer possible; if contact surface

for cylinder head cover is rough or

damaged; or if there are cracks between

the valve seats.

Check that the inside diameter of each

valve guide does not exceed 0.2780 inch

(7.059 mm).

Check that valve seat angle does not exceed 45 degrees.

Clean valves with diesel fuel oil and dry with com-

pressed air.

Inspect valves for warpage, burning, or other

damage.

Inspect valve stems for scratches, scuff marks, or

other damage.

Inspect valve tulips, faces, and heads for pitting,

ridges, or cracks.

Check that each valve stem diameter is not less

than 0.2716 inch (6.95 mm).

Check that each valve head diameter is not less than 1.200 inches (30.5 mm).

1

2

3

4

If the inside diameter of a cylinder head valve guide (1)

exceeds 0.2780 inch (7.059 mm), replace valve guide.

Press out valve guide using mandrel 669 347 00.

From cylinder head bottom, push valve guide (1) out

of cylinder head (2). Insert new valve guide (1) into

cylinder head (2). install new valve guide by pressing

in with mandrel 669 347 00. Minimum inserting

pressure is 220 inch-pounds (245 cm·kg).

Ream the inside diameter of the valve guide to

0.2756/0.2759 inch (7.000/7.009 mm) using hand

reamer 612 107 00.

Repair defective cylinder head valve seats by re-

cutting with a 45 degree valve seat cutter. Recut valve

seats with valve reseating tool 612 103 00, guiding pin 612 104 00, and handle for valve reseating

tool 670 323 00. Cut until valve seat is absolutely clean.

6-3

|