|

|||

|

|

|||

|

Page Title:

Section III. REPAIR OF RADIATOR |

|

||

| ||||||||||

|

|

TM 5-4320-234-34

b.

Install the magneto (TM 5-4320-234-14, para 4-

35).

c.

Adjust the governor (TM 5-4320-234-12, para 4-

27).

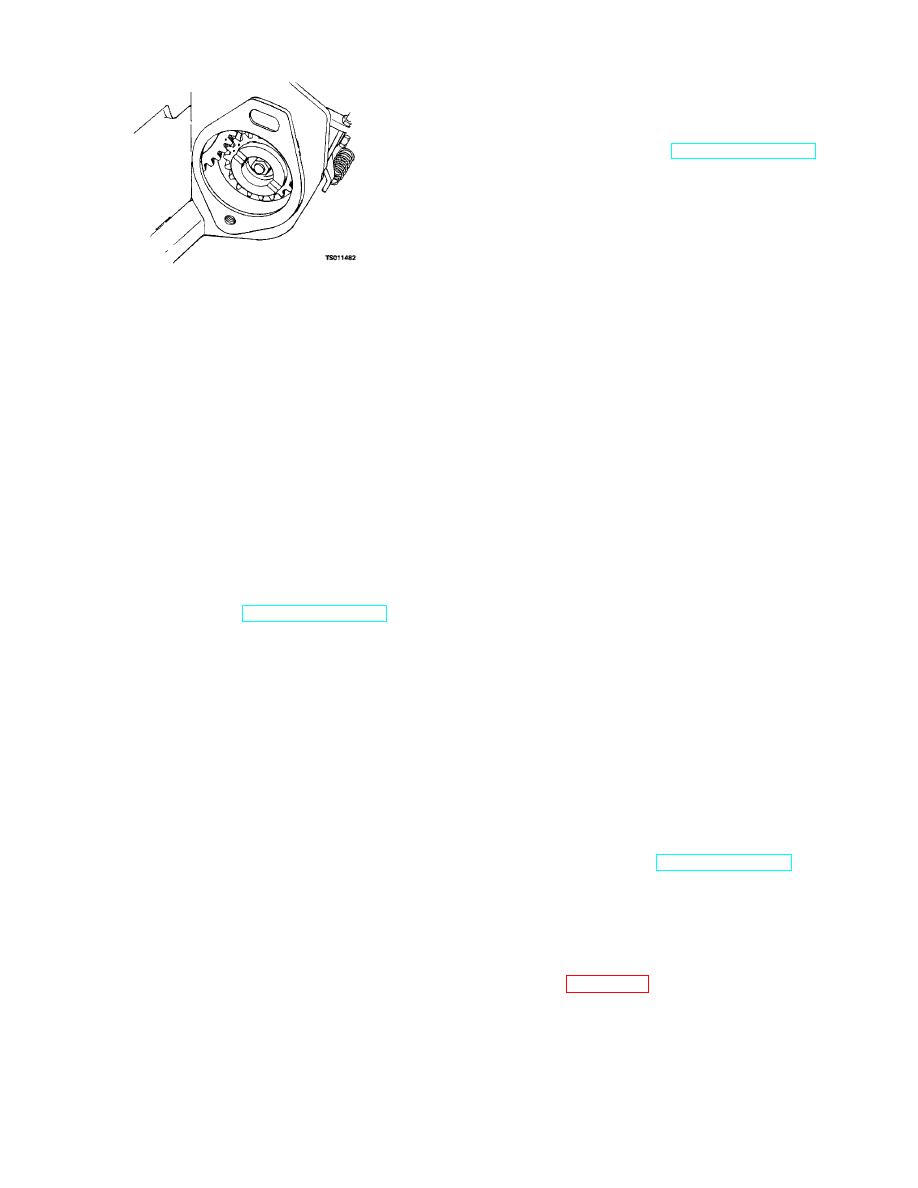

Figure 3-3. Timing marks on governor drive gear and

cam gear.

Section III. REPAIR OF RADIATOR

CAUTION

3-7. Description

Do not exceed 10 psi air pressure for

Liquid coolant is pumped through passages in the

radiator testing.

Excess pressure will

engine to remove the heat of combustion. As the hot

damage the radiator. Make sure that you

coolant is pumped from the engine, it enters the

completely drain the radiator core before

radiator, which is a large heat exchanger consisting of

testing. When testing at low pressure, it is

tubes and fins that dissipate the heat to the atmosphere.

possible that water within the core could

The fluid passes into the top of the radiator and out

prevent air from passing out of small

through the bottom. The cooling fan maintains a blast

holes, and the leaks could remain

of air through the radiator to help dissipate the heat.

undetected.

The coolant from the radiator is recirculated through the

engine to complete the cycle.

b.

Make sure the radiator is completely drained

of coolant. Plug all openings, except one through which

3-8. Removal

compressed air can be applied. Immerse the radiator in

Remove the radiator (TM 5-4320-234-12, para 4-

a tank of water and apply 10 psi air pressure to the

32).

interior of the radiator. Check for air bubbles that could

indicate leaks. If leaks are found, mark the areas for

3-9. Cleaning

repairs.

a.

You may clean the exterior of the radiator by

c.

Inspect all hardware for cracks and for worn

flushing in a reverse-flow direction with a stream of

or stripped threads.

water to remove all bugs and debris. Remove any

greasy or oil deposits with cleaning solvent (Fed. Spec.

d.

Replace all parts damaged beyond repair.

P-D-680).

3-11. Repair

b.

Reverse-flush the interior of the radiator,

a.

Repair leaks by soldering. Be sure that you

using a flushing gun.

do not block or retard circulation through any tubes.

c.

If flushing fails to remove scale from the

There shall be no blocked tubes upon completion of

interior of the radiator, boil it out in accordance with

repairs.

current directives.

3-12. Installation

3-10. Inspection and Testing

Install the radiator (TM 5-4320-234-12, para 4-32).

a.

Inspect all parts for cracks, leaking tubes or

gaskets, damaged threads, or other obvious damage.

Section IV. REPAIR OF OIL SYSTEM COMPONENTS

3-13. Description of Engine Oil System

the main bearing caps of the engine.

Internal

components of the engine lubrication system are

a.

The engine oil syste provides lubrication

m

covered in Chapter 4, which describes basic engine

for the working surfaces within the engine. The oil is

repair and overhaul.

retained in the oil pan under the engine and is circulated

through the engine by the oil pump mounted on one of

b.

An oil filter with its related piping is mounted

3-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |