|

|||

|

|

|||

|

Page Title:

Section II. MOVEMENT TO A NEW WORKSITE |

|

||

| ||||||||||

|

|

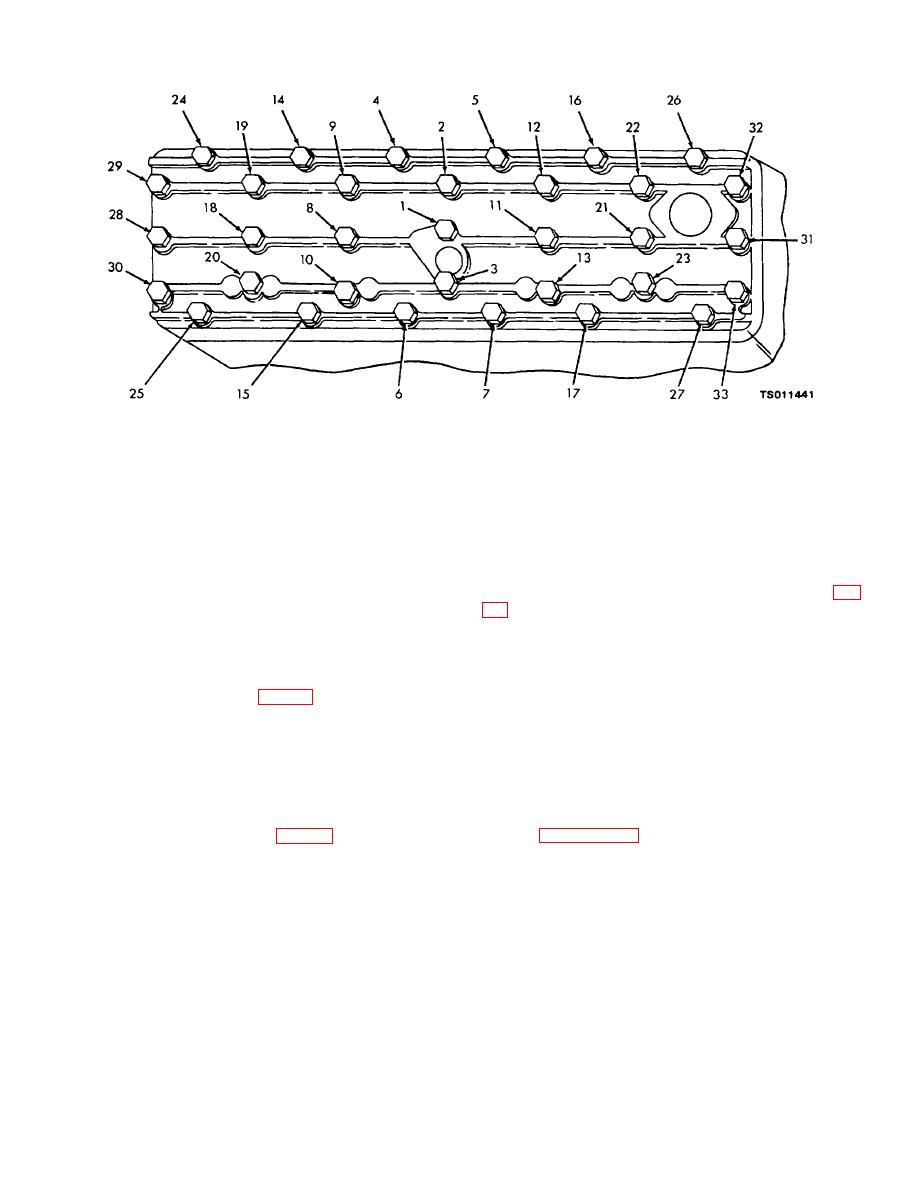

Figure 4-3. Cylinder head bolt tightening sequence.

Section II. MOVEMENT TO A NEW WORKSITE

4-3. Dismantling for Movement

f. Remove the pin from each rear stand and slide

the leg up to its highest position. Reinsert the pin to

Dismantle the pump for movement to a new worksite as

secure it in the raised position. Hitch the tow bar (1, fig.

follows:

a. Disconnect the suction line and discharge line

secured. Connect the electrical cable to the receptacle

on the towing vehicle and connect the safety chains (2).

from the pump. If possible, drain the lines before

Remove the pin (3) and raise the front leg (4). Reinsert

disconnecting them from the pump.

the pin to secure the leg. Remove the chock blocks

from under the chassis wheels.

of the pump to drain the pump housing. Catch the fluid

g. Before moving the unit, check that the stop, tail,

in a suitable container.

and directional lights all light in response to operation of

c. Cover the pump suction and discharge openings

controls on the towing vehicle.

by installing the caps provided.

4-4. Reinstallation after Movement

d. If installed, disconnect the fuel line from the 3-

Refer to paragraph 4-2 for installation instructions.

way fuel source selector valve (5, fig. 2-2) on the fuel

tank.

Section III. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT

4-5. Tools and Equipment

4-7. Maintenance Repair Parts

There are no tools, equipment, or repair parts issued

Repair parts and equipment are listed in the repair parts

with the pump assembly.

and special tools list covering organizational

maintenance for this equipment. Refer to TM 5-4320-

4-6. Special Tools and Equipment

234-20P.

No special tools or equipment is required for

organizational maintenance of the pump assembly.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |