|

| |

APPENDIX A

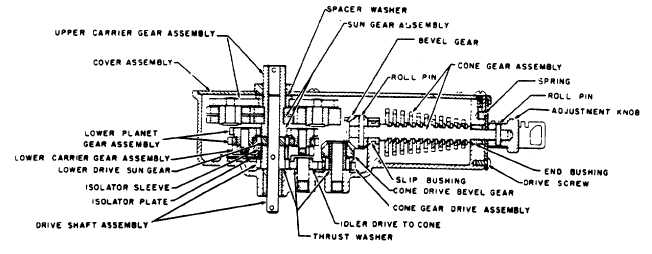

FIG. 20.

After adjustment is completed and the access cover

replaced, it should be sealed to prevent tampering or

unauthorized changing of the adjustment.

DISASSEMBLY

First remove the cover. Lift off the upper carrier gear,

sungear assembly, two lower planet gear assemblies,

lower driving sun gear, lower carrier gear assembly,

isolator sleeve, isolator plate and drive shaft assembly.

Next, drive out the roll pin and remove the adjustment

knob. Remove the adjustment plate drive screw,

adjustment plate and spring. This will allow the three

end bushings to be removed.

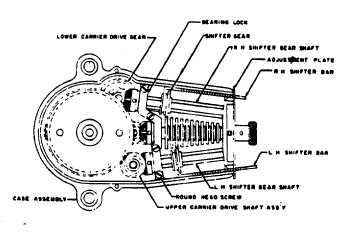

FIG. 21.

Next, remove the bearing lock and lift out the right and

left hand shifter assemblies and the cone drive gear

assembly. Remove the upper carrier drive shaft

assembly, lower carrier drive gear, cone drive bevel

gear, cone drive gear assembly and idler gear.

All parts showing excessive wear should be replaced. If

the case bushing is worn it is recommended that the

case assembly be replaced, rather " than the bushing,

as it is necessary to machine finish the bushings after

assembly to the case. See Parts List 3-C for

replacement part numbers.

Reassemble in reverse order of disassembly, with the

following precautions:

1. Add 14312 - 1 washers behind bevel gears until

ends of teeth line up and minimum backlash is

obtained.

2. Be sure the isolator plate key is engaged in the

keyway of the isolator sleeve and that the slot

engages the stop pin.

3. When assembling the two lower plane gears to the

lower carrier gear, note that each gear has a

center punch mark at one of the teeth. Point the

marked tooth of one gear at the drive shaft and

the other at a 900 angle to the drive shaft, Figure

21. This is necessary to allow the sun gear

assembly to mesh with the planet gears.

The "G" calibrator requires only a light coat of oil as all

gears have an electro-film coating which is self-

lubricating. Use S. A. E. 10 or lighter oil,.

PRINTED IN USA

A9-32

|