|

| |

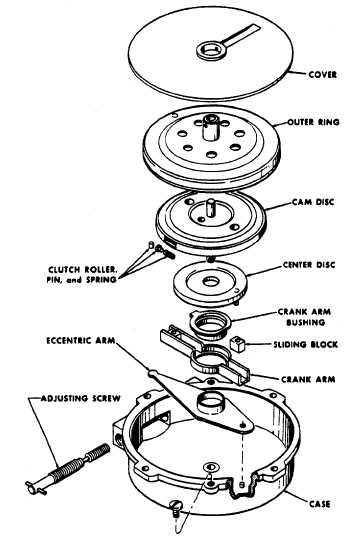

FIG. 16. CLUTCH TYPE CALIBRATOR.

For the purpose of adjustment, A.O. Smith meters are

equipped with a calibrator. Calibrators are of two

designs, the Clutch Type and the type G or Gear Type.

CLUTCH TYPE

The clutch type calibrator, Figure 16, utilizes two

overriding clutches and an eccentric. By adjusting the

amount of eccentricity the calibrator can be made to

vary any drive ratio between the meter and the register

by a maximum total of 11 percent.

This calibrating means is used for adjusting for

variations

in

operating

conditions,

differences

in

viscosity of product metered, as well as for providing

automatic temperature compensation.

OPERATION

The nature of the device is such that a correction

impulse is imparted to the calibrator output shaft once

during each revolution. This means that on a standard

Model "S" Meter which is geared to register 5 gallons for

each revolution of the calibrating or output shaft, there

will be one correction impulse for each five gal Ions. To

reduce wear to a minimum and to obtain maximum

accuracy in frequency of operation of the correction

device, the cycle has been reduced to one impulse per

barrel on the large capacity, continuous service meters,

hence a standard Model W, D or M-60 Meter which is

geared to one 42 gallon barrel per revolution of the

output shaft will have a correction cycle for each barrel.

Small capacity meters such as the Model T-10 Truck

Meters are geared one revolution per gallon and

consequently receive one correction impulse per gallon.

TEMPERATURE COMPENSATION

Temperature

compensation

is

accomplished

by

adjusting the amount of eccentricity of the calibrator

eccentric arm automatically by utilizing a thermostatic

bulb and bellows assembly ( see Figure 17).

The Smith meter accurately measures the actual

volume of the liquid passing through it, regardless of

temperature.

The Smith Temperature Compensator consists of a

thermostatic bulb connected by a capillary tube to a

metal sylphon bellows.

A9-28

|