|

| |

APPENDIX A

APPENDIX

GAUGE REPLACEMENT PROCEDURES

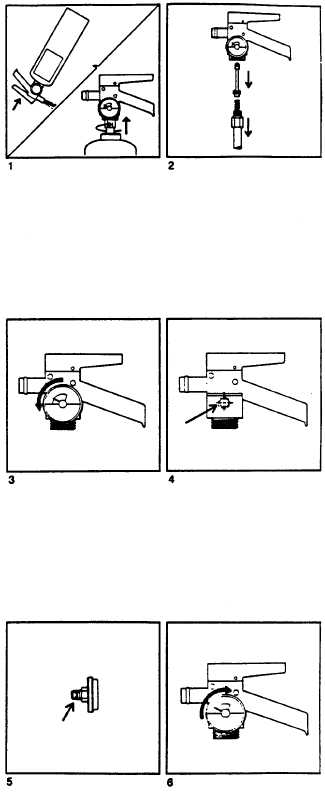

1.

Invert the extinguisher and press the lever to

release all pressure. (On Halon 1211 models,

inverting is not necessary; also if agent

reclaiming is desired, see page 12 of Appendix.)

Remove valve assembly.

2.

Disassemble the valve assembly, removing the

pick-up tube, valve stem, and spring.

3.

Remove damaged/defective gauge.

4.

Clean the gauge port thread. Use 1/8 in. NPT

pipe tap to chase threads, if necessary. Be

careful not to tap too deep as gauge will not

tighten properly and valve assembly will have to

be replaced.

5.

Apply plastic lead pipe sealant (ARMSTRONG

C-4 w/Activator W or equivalent) to the thread

of the new gauge. Be careful not to get any

sealant into the hole in the face of the gauge

socket. Ansul does not recommend the use of

pipe tape.

6.

Screw the new gauge into the valve body

making certain that the GREEN operating range

on the gauge face ia pointed to the top of the

valve.

A8-7

|