|

|||

|

|

|||

|

Page Title:

Emergency Repairs with Sealing Clamps |

|

||

| ||||||||||

|

|

TM 10-5430-238-12&P

0006 00

Emergency Repairs with Sealing Clamps

Small slits, tears, or cuts [not to exceed 6-inches (15.24 centimeters) in length] may be repaired with

sealing clamps.

The size of the damaged area (opening) needing repair will govern the size of the clamp needed. Select

clamp size as follows:

1. For holes (tears) less than 2-inches (5.08 centimeters) in length, use the 3.0-inch (7.6 centimeters)

clamp.

2. For holes (tears) 2 to 4 inches (5.08 to 10.16 centimeters) in length, use the 5-inch (12.7 centimeters)

clamp.

3. For holes (tears) 4 to 6-inches (10.16 to 15.24 centimeters) in length, use the 7.5-inch (19 centimeters)

clamp.

WARNING

It may be necessary to increase the size of the tear in order to insert the bottom

plate of the clamp. Be careful when installing a sealing clamp in the tank. Fuel

will pour out when a larger slit is made in the tank. Leaking fuel can cause

personal injury, fire, explosion, or loss of government property.

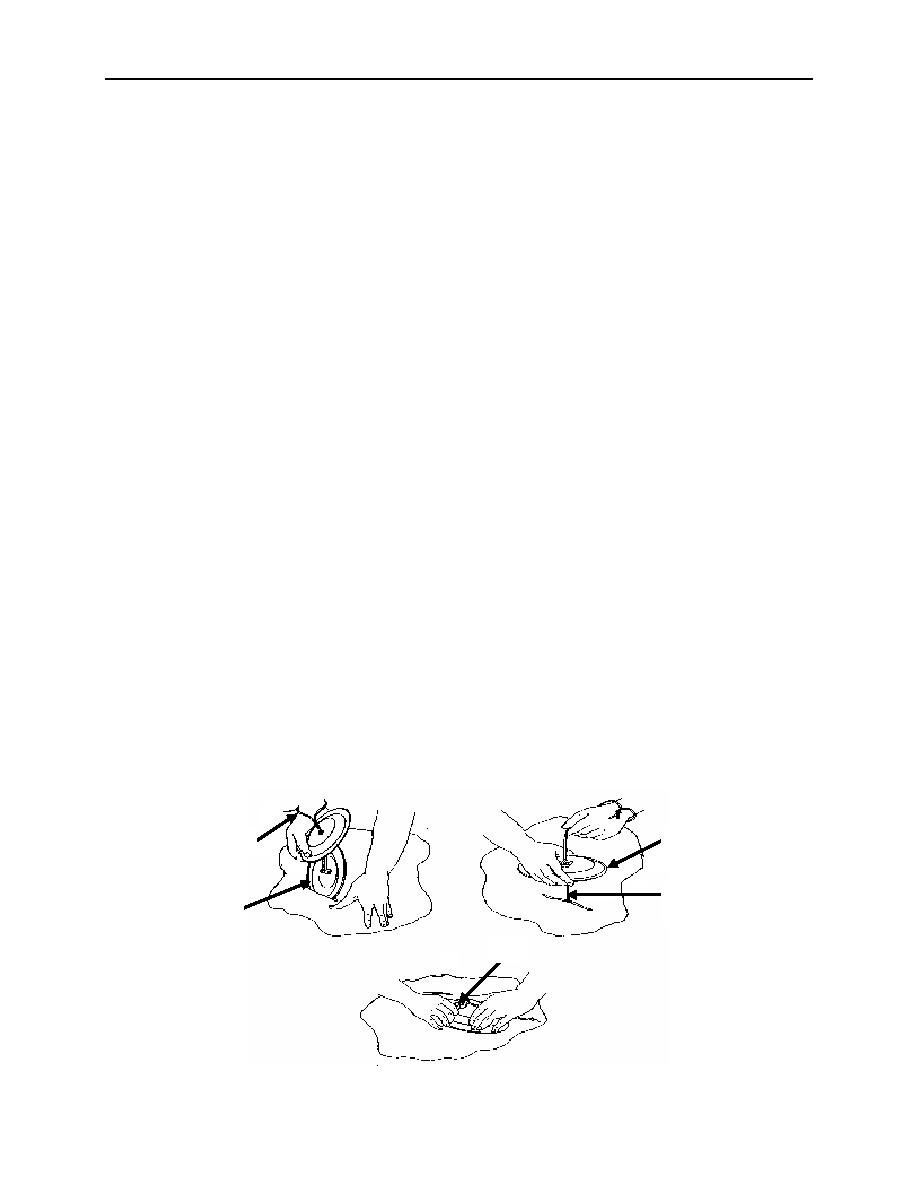

4. Loop cord around wrist (1) to prevent loss of the clamp into tank.

5. Insert the bottom plate (2) of the clamp through the hole or tear and rotate it until it is centered, and its

length runs with the tear.

6. Pull the bottom plate up against the fabric, and slide the top plate (3) and wing nut (4) down the cord

and onto the threaded stud (5) of the bottom plate.

CAUTION

Do not over tighten the wing nut, as stud threads may be stripped, or damage to

the tank fabric may occur.

7. With the plates aligned, tighten the wing nut (4), clamping the tank wall between the two plates.

Tighten the wing nut enough to stop the leak.

1

3

5

2

4

Installation of Sealing Clamps

0006 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |