|

| |

TM 10-5430-232-12&P

Table 2-1. Operator Preventive Maintenance Checks and Services for 5,000 Barrel Fabric

Collapsible Petroleum Tank Models BA91-142 and RCF0210000

Item

No.

Interval

Location

Item to be

checked

or

serviced

Procedure

Not Fully Mission

Capable If:

10

During

Tank

Inspect for tears, punctures or leaks.

Tank is torn, punctured, or has

Class III leaks (exclude wet

spots).

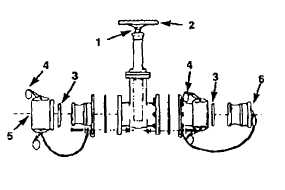

11

During

Gate

Valve

Check for leaks, bent or binding stem

(1), broken handwheel (2). Check

gaskets (3) and cam-lever arms (4) for

damage. Check dust cap (5) and dust

plug (6) for damaged or missing chain.

Stem, handwheel, gasket, or

cam-lever arms are damaged

missing, or has, Class Ill leaks.

12

During

Filler and

discharge

hose

assembly

Check for leaks, cuts and tears.

Hose assembly leaks or is

damaged.

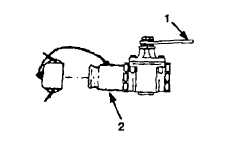

13

During

Drain

valve

Check for leakage, broken handle (1),

and for damaged or broken cam lock

adapter (2).

Stem

and/or

handle

are

damaged, missing, or drain

valve has Class III leaks.

14

During

Drain hose

assembly

Check for leaks, cuts and tears. Check

fittings for distortion and damage.

Hose assembly is damaged or

has Class III leaks.

Change 2 2-8

|