|

| |

TM 10-4930-250-13&P

Table2-3. Operator'sPreventiveMaintenanceChecksandServicesforAAFARS(continued)

Item

Interval

Location

Procedure

Not Fully Mission

No.

Item to

Capable If:

Check/

Service

7

Before

Fuel Hoses

Inspect for damage, cuts, nicks, abrasions, blistering, or coupling

Slippage, hoses are

slippage. Coupling slippage usually shows first as a misalignment of the damaged. Soft

hose and coupling or as a scored or freshly exposed part of the hose

spots.

where the slippage has occurred. If a coupling is slipping or leaking

remove the hose from service. Most hose failures occur within 12

inches of couplings. Check all the way around the hose. Press lightly

and feel for soft spots. If a soft spot is found remove the hose from

service.

8

Before

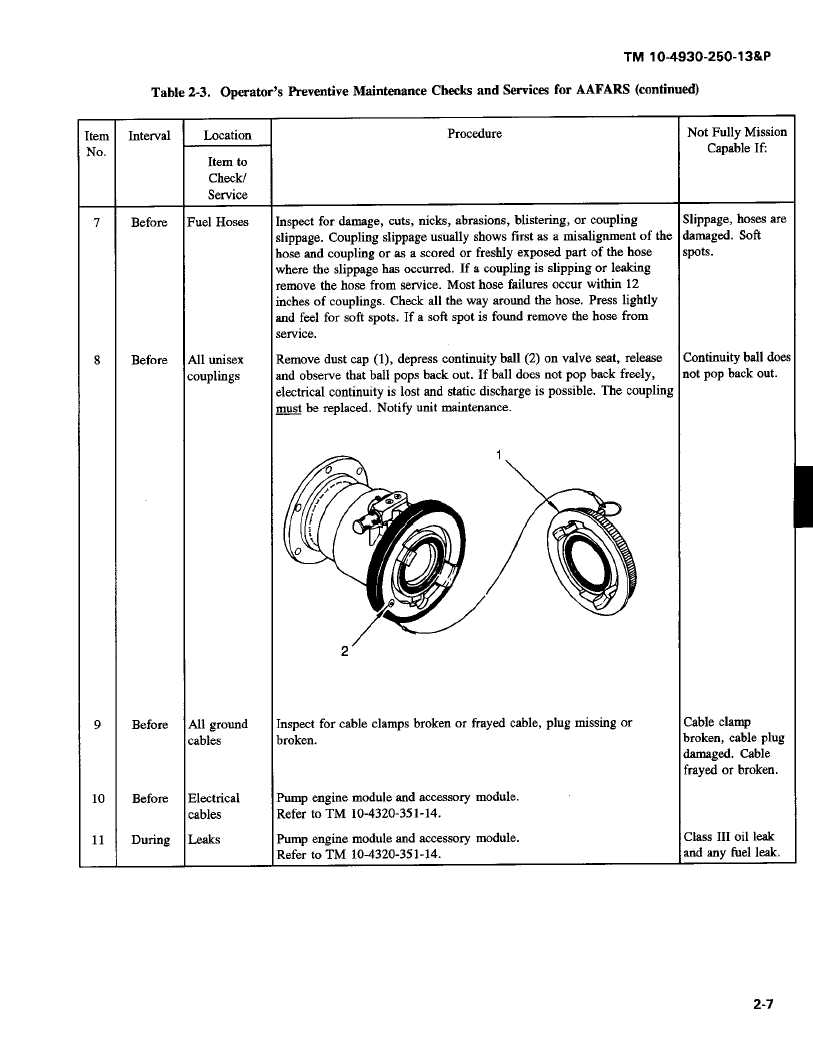

All unisex

Remove dust rap (1), depress continuity ball (2) on valve seat, release

Continuity ball does

couplings

and observe that ball pops back out. If ball does not pop back freely,

not pop back out.

electrical continuity is lost and static discharge is possible. The coupling

must be replaced. Notify unit maintenance.

0

2

9

Before

All ground

Inspect for cable clamps broken or frayed cable, plug missing or

Cable clamp

cables

broken.

broken, cable plug

damaged. Cable

frayed or broken.

10

Before

Electrical

Pump engine module and accessory module.

cables

Refer to TM 10-4320-351-14.

11

During

Leaks

Pump engine module and accessory module.

Class III oil leak

Refer to TM 104320-351-14.

land any fuel leak.

2-7

|