|

| |

TM 10-4930-248-13&P

5-3.

CCR NOZZLE,

PISTON

MODEL,

ASSEMBLY

REPAIR - continued.

(f)

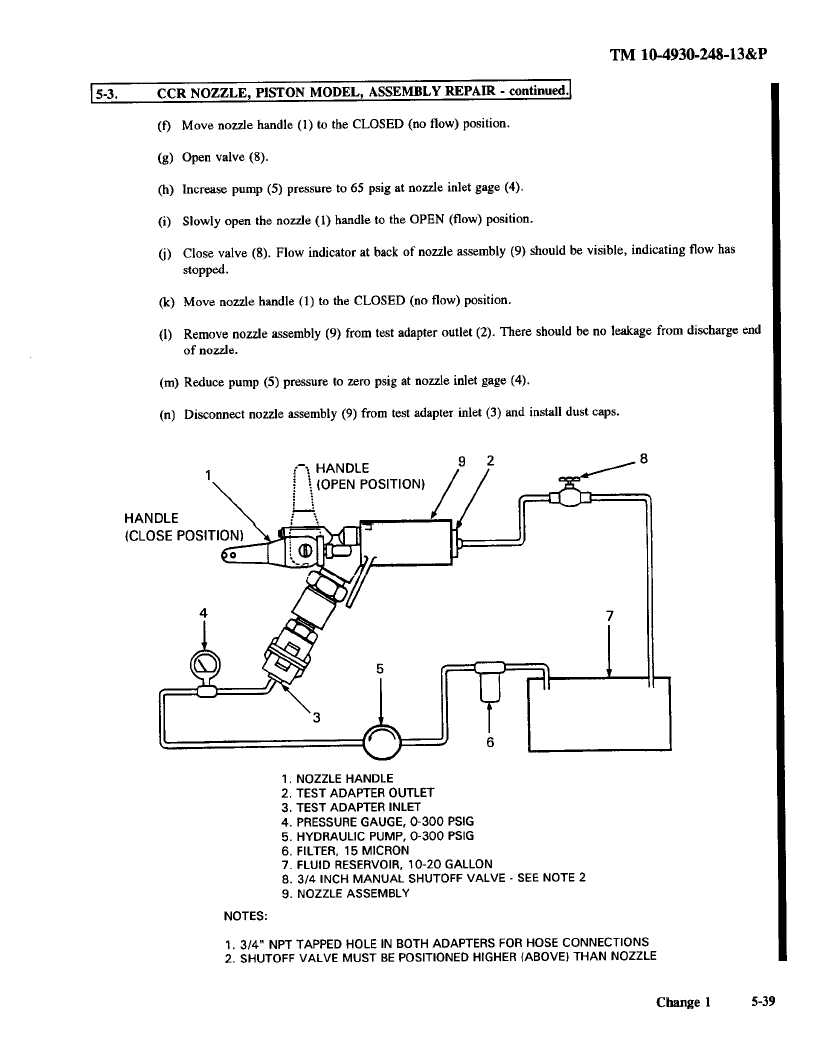

Move nozzle handle (1) to the CLOSED (no flow) position.

(g)

Open valve (8).

(h) Increase pump (5) pressure to 65 psig at nozzle inlet gage (4).

(i) Slowly open the nozzle (1) handle to the OPEN (flow) position.

0)

Close valve (8). Flow indicator at back of nozzle assembly (9) should be visible, indicating flow has

stopped.

(k)

Move nozzle handle (1) to the CLOSED (no flow) position.

(1)

Remove nozzle assembly (9) from test adapter outlet (2). There should be no leakage from discharge end

of nozzle.

(m) Reduce pump (5) pressure to zero psig at nozzle inlet gage (4).

(n) Disconnect nozzle assembly (9) from test adapter inlet (3) and install dust caps.

HANDLE

9

2

8

(OPEN POSITION)

HANDLE

(CLOSE POSITION)

a

4

7

5

3

6

1. NOZZLE HANDLE

2. TEST ADAPTER OUTLET

3. TEST ADAPTER INLET

4. PRESSURE GAUGE, 0-300 PSIG

5. HYDRAULIC PUMP, 0-300 PSIG

6. FILTER, 15 MICRON

7. FLUID RESERVOIR, 10-20 GALLON

8. 3/4 INCH MANUAL SHUTOFF VALVE - SEE NOTE 2

9. NOZZLE ASSEMBLY

NOTES:

1. 3/4" NPT TAPPED HOLE IN BOTH ADAPTERS FOR HOSE CONNECTIONS

2. SHUTOFF VALVE MUST BE POSITIONED HIGHER (ABOVE) THAN NOZZLE

Change

1

5-39

|