|

| |

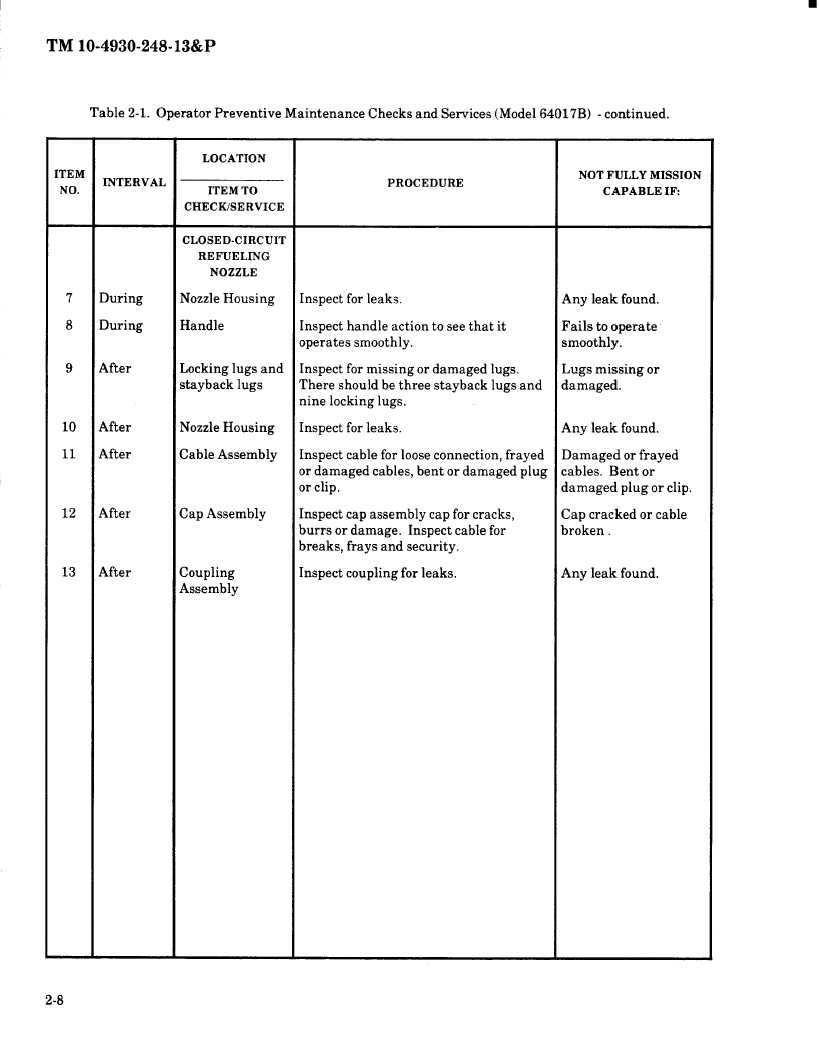

TM 10-4930-248-13&P

Table

2-1. Operator

Preventive

Maintenance

Checks

and Services

(Model 64017B)

- continued.

LOCATION

ITEM

INTERVAL

PROCEDURE

NOT FULLY MISSION

NO.

ITEM TO

CAPABLE IF:

CHECK/SERVICE

CLOSED-CIRCUIT

REFUELING

NOZZLE

7

During

Nozzle Housing

Inspect

for leaks.

Any leak found.

8

During

Handle

Inspect

handle

action to see that it

Fails to operate

operates

smoothly.

smoothly.

9

After

Locking

lugs and

Inspect

for missing

or damaged

lugs.

Lugs

missing

or

stayback

lugs

There

should

be three

stayback

lugs and

damaged.

nine locking

lugs.

10

After

Nozzle

Housing

Inspect

for leaks.

Any leak found.

11

After

Cable

Assembly

Inspect

cable for loose connection,

frayed

Damaged

or frayed

or damaged

cables,

bent

or damaged

plug

cables.

Bent or

or clip.

damaged

plug or clip.

12

After

Cap Assembly

Inspect

cap assembly

cap for cracks,

Cap cracked

or cable

burrs

or damage.

Inspect

cable for

broken.

breaks,

frays and security.

13

After

Coupling

Inspect

coupling

for leaks.

Any leak found.

Assembly

2-8

|