|

| |

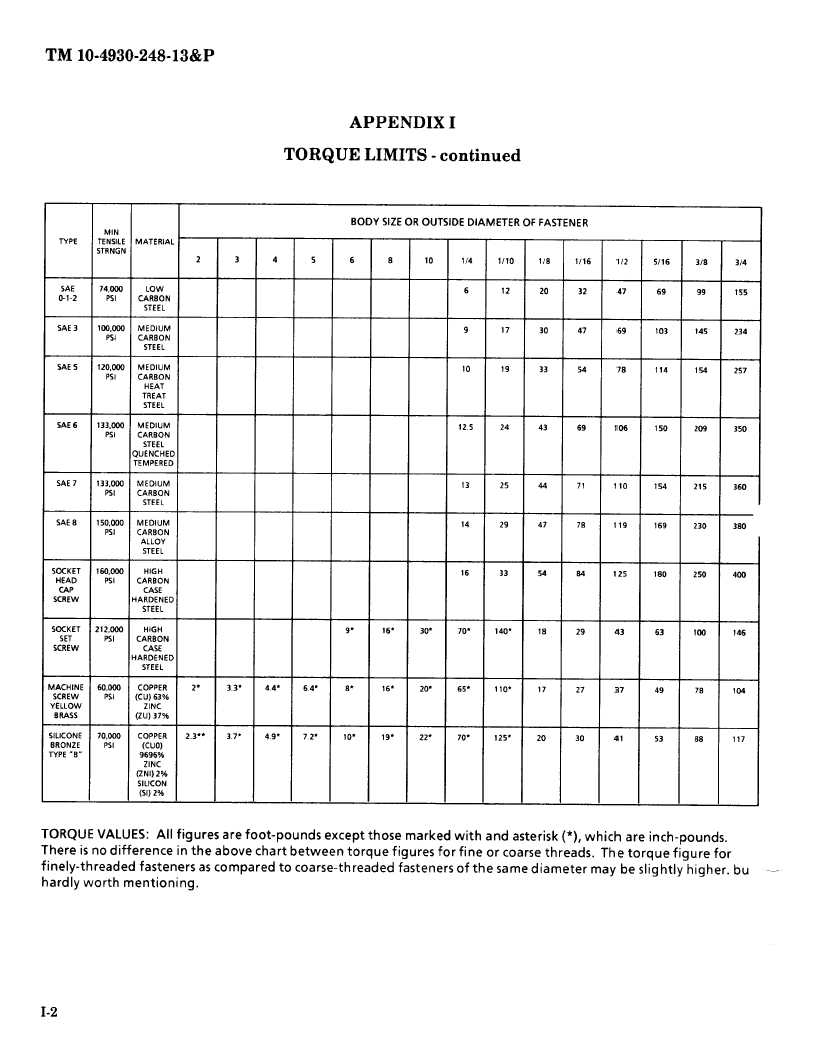

TM 10-4930-248-13&P

APPENDIX

I

TORQUE

LIMITS

- continued

BODY SIZE OR OUTSIDE

DIAMETER

OF FASTENER

MIN

TYPE

TENSILE

MATERIAL

STRNGN

2

3

4

5

6

8

10

1/4

1/10

118

1/16

112

5116

3/8

3/4

SAE

74,000

LOW

6

12

20

32

47

69

99

155

0-1-2

PSI

CARBON

STEEL

SAE 3

100,000

MEDIUM

9

17

30

47

69

103

145

234

PSI

CARBON

STEEL

SAE 5

120,000

MEDIUM

10

19

11

-14

78

114

154

217

PSI

CARBON

HEAT

TREAT

STEEL

SAE 6

133,000

MEDIUM

12.5

24

43

69

106

150

209

350

PSI

CARBON

STEEL

QUENCHED

TEMPERED

SAE7

133,000

MEDIUM

13

25

44

71

110

154

215

360

PSI

CARBON

STEEL

I

SAE8

150,OGO

MEDIUM

14

29

41

71

119

169

130

380

PSI

CARBON

ALLOY

STEEL

SOCKET

160,000

HIGH

16

33

54

84

121

180

250

400

HEAD

PSI

CARBON

CAP

CASE

SCREW

HARDENED

STEEL

SOCKET

212,DOO

HIGH

9.

16*

30*

70*

140*

is

29

43

63

100

146

SET

PSI

CARBON

SCREW

CASE

HARDENED

STEEL

MACHINE

60,000

COPPER

2*

3.3*

4.4*

6.4*

8*

16*

20*

65*

110*

17

27

37

49

78

104

SCREW

PSI

(CU) 63%

YELLOW

ZINC

BRASS

(ZU)37%

SILICONE

70,000

COPPER

2.3'*

3.7

4.9

7.2*

10*

19*

22*

70*

125*

20

30

41

53

88

117

BRONZE

PSI

(CUO)

TYPE "B"

9696%

ZINC

(ZNI)2%

SILICON

(SI)2%

TORQUE VALUES: All figures

are foot-pounds

except

those

marked

with and asterisk

(*), which are inch-pounds.

There

is no difference

in the above

chart between

torque

figures

for fine or coarse threads.

The torque

figure

for

finely-threaded

fasteners

as compared

to coarse-threaded

fasteners

of the same diameter

may be slightly

higher.

bu

hardly worth

mentioning.

I-2

|