|

| |

TM 10-4930-247-13&P

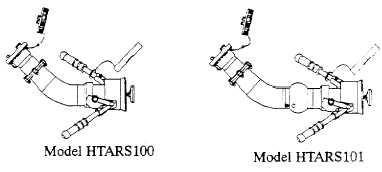

Table 2-1. Operator Preventive Maintenance Checks and Services For

Models HTARS100 and HTARS101 - cont.

Item

Location

No.

Interval

Item

Procedure

Not Fully Missi on

Check/Service

Capable If:

3

Before

Single Point

a. Inspect nozzle for cracks and loose, bent

Nozzle body cracked;

Refueling Nozzle

or broken locking handles.

locking handles

broken.

b. Inspect control lever for cracks.

Control lever cracked.

c. Inspect nozzle collar for rocks or debris

stuck in adapter locking grooves. Clean as

required.

d. Inspect adapter end of nozzle for

Adapter cracked or

excessive wear, cracks or damage.

damaged.

e. Inspect non-valved dry break couplings

Locking pin stuck.

for stuck locking pin, broken lock lugs and

seal damaged or

damaged or missing seal.

missing. locking lugs

cracked or damaged.

f. Inspect for damaged or missing dust cap

and dust cover.

4

Before

Recirculation

a. Inspect nozzle body for cracks and

Nozzle cracked;

Nozzle

loose, bent or broken locking handles,

locking handles

broken.

b. Inspect control lever for cracks.

Control lever cracked

or broken.

c. Inspect nozzle collar for rocks or debris

stuck in adapter locking grooves. Clean as

required.

d. Inspect adapter end of nozzle for

Adapter cracked or

excessive wear, cracks or damage.

damaged.

Change 4 2-11

|