|

| |

TM 10-4930-247-13&P

4-17.

2-INCH FUEL HOSE ASSEMBLY HOSE REPAIR -cont.

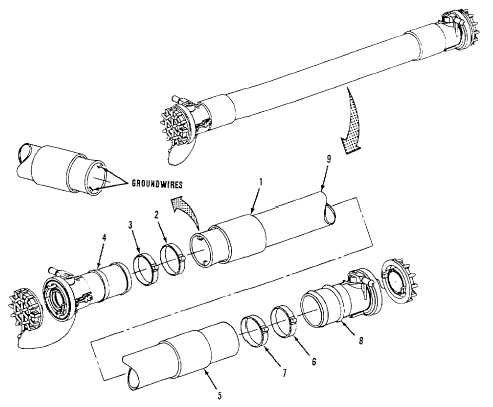

Figure 4-7. 2-Inch Fuel Hose Repair.

c.

Inspection. Refer to figure 4-7.

(1)

Inspect valved dry break coupling assemblies (4 and 8) for cracks, corrosion and damaged coupling ends.

(2)

Inspect hose (9) for cuts, tears, punctures, bulges and delamination.

(3)

Inspect ends of hose (9) for damaged or missing ground wires. Perform continuity test of ground wires from one

end of hose to the other. Continuity must exist.

(4)

Inspect ground wires at both ends of hose (9). At least 1/2 inch of wire must be exposed. If required, trim back

hose material to obtain correct wire length.

d.

Repair.

(1)

Replace damaged components and all mandatory replacement parts.

(2)

Repair valved dry break coupling assemblies (para 4-18).

e.

Assembly. Refer to figure 4-7.

(1)

Slide sleeve (5) onto hose (9) and position it about 12 inches back from end of hose.

(2)

Fold ends of grounding wires into hose (9).

4-27

|