|

| |

TM 10-4930-246-13&P

b. NozzleDisconnbction.

DISCONNECT NOZZLE FROM VEHICLE

Make sure nozzle is disconnected from vehicle at loading and unloading stations before

vehicle is moved.

(1) Rotate the lever (9) to the CLOSE position until it is against the internal mechanical stop (approximately

200 degrees).

If the lever is not against the internal closed stop, with the linkage over center,

internal pressure will force the poppet open allowing fuel to spill.

(2) Check that lever (9) is fully closed. Grasp the handles(5) androtate the collar (6) counter-clockwise until

the nozzle is released from the adapter (approximately 30-35 degrees).

(3) Examine the connection end of the nozzle and verify that all three collar lock pins (8) have been released into

the cutouts in the collar (6) flange. Squeezehandle (5) and lever (9) together to cause collar lock pins to spring into

cutouts.

(4) If pins were not properly released, notify vehicle operator and your supervisor that the adapter on the item

being fueled needs inspection and possible replacement.

(5) Disconnect bondingcable (4).

(6) Place protective plastic cap (1) on nozzle end.

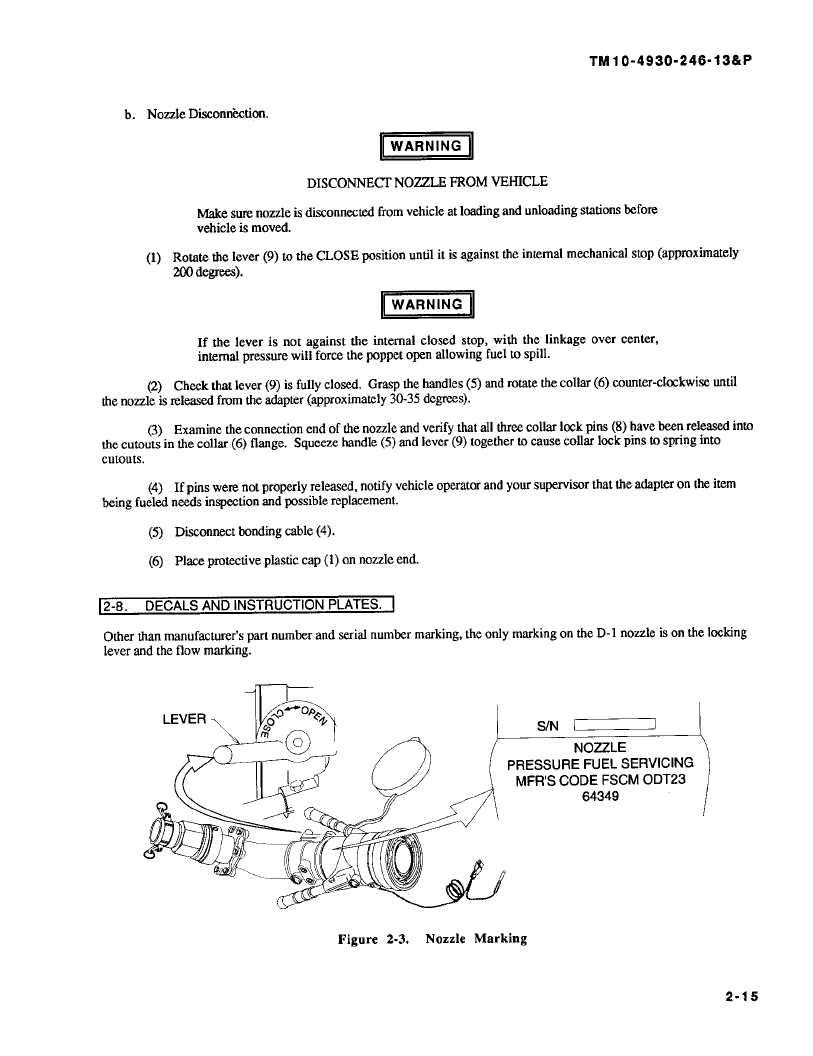

2-8.

DECALS AND INSTRUCTION PLATES.

Other than manufacturer's part number and serial number marking, the only marking on the D-1 nozzle is on the locking

lever and the flow marking.

LEVER

@op

S/N

NOZZLE

PRESSURE FUEL SERVICING

MFR'S CODE FSCM ODT23

6434

Figure

2-3.

Nozzle Marking

2-15

|