|

| |

TM 10-4930-246-13&P

Table 2-1. Operator PreventiveMaintenanceChecksand Servicesfor D-1 Nozzle- continued

Location

Item

Interval

Item to Check/Service

Procedure

Not Fully Mission Capable If:

No.

10

After

Grounding Cable

Check that grounding cable is,

Grounding cable, bonding plug,

Assembly

bonding plug, and grounding clip

and grounding clip are broken or

are place and in good condition.

missing.

11

After

Handles

Check that handles are in place

Handles missing or damaged

and in good condition.

enough to interfere with

operation.

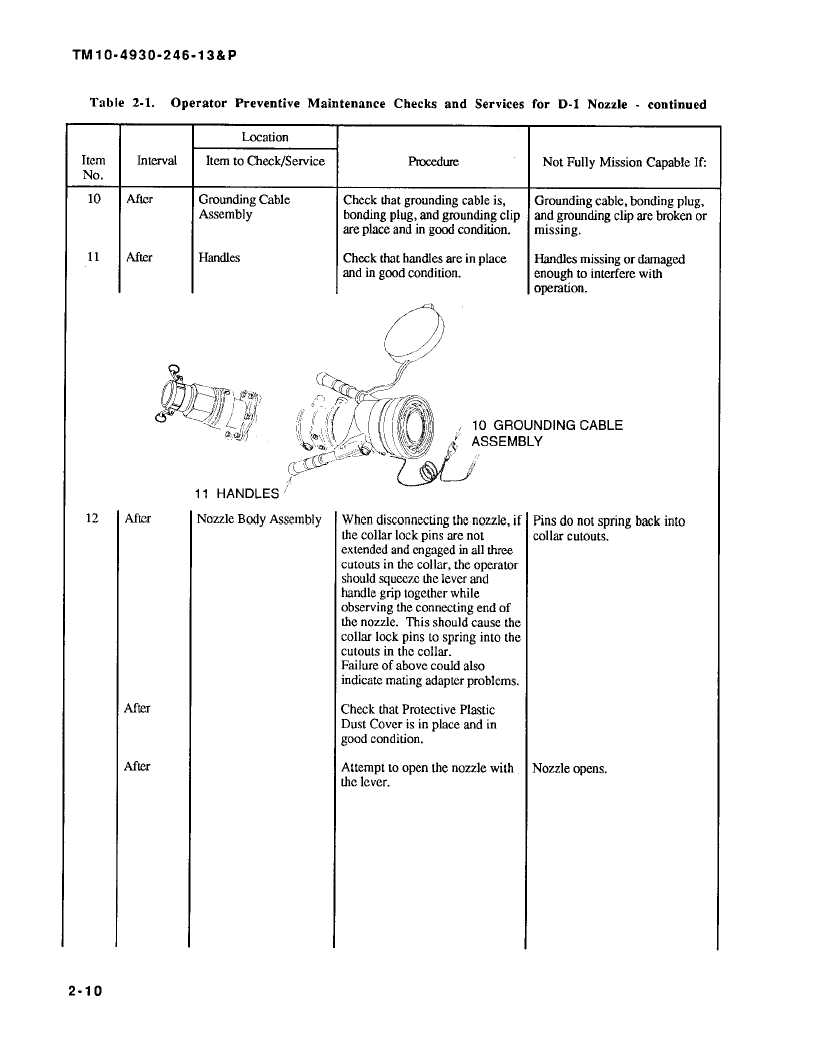

10 GROUNDING

CABLE

@,VA,V

ASSEMBLY

V-,

11 HANDLES'

12

After

Nozzle Body Assembly

When disconnecting the nozzle, if

Pins do not spring back into

the collar lock pins are not

collar cutouts.

extended and engaged in all three

cutouts in the collar, the operator

should squeeze the lever and

handle grip together while

observing the connecting end of

the nozzle. This should cause the

collar lock pins to spring into the

cutouts in the collar.

Failure of above could also

indicate mating adapter problems.

After

Check that Protective Plastic

Dust Cover is in place and in

good condition.

After

Attempt to open the nozzle with

Nozzle opens.

the lever.

2-10

|