|

| |

TM 10-4930-242-13&P

Table 2-1. Operator Preventive Maintenance Checks and Services.

NOTE: Within designated interval, these checks are to be performed in the order listed

Item

Interval

Location

Crew -member

Not Fully Mission Capable If:

No.

Item to Check/Service

Procedure

D-1 NOZZLE

ASSEMBLY

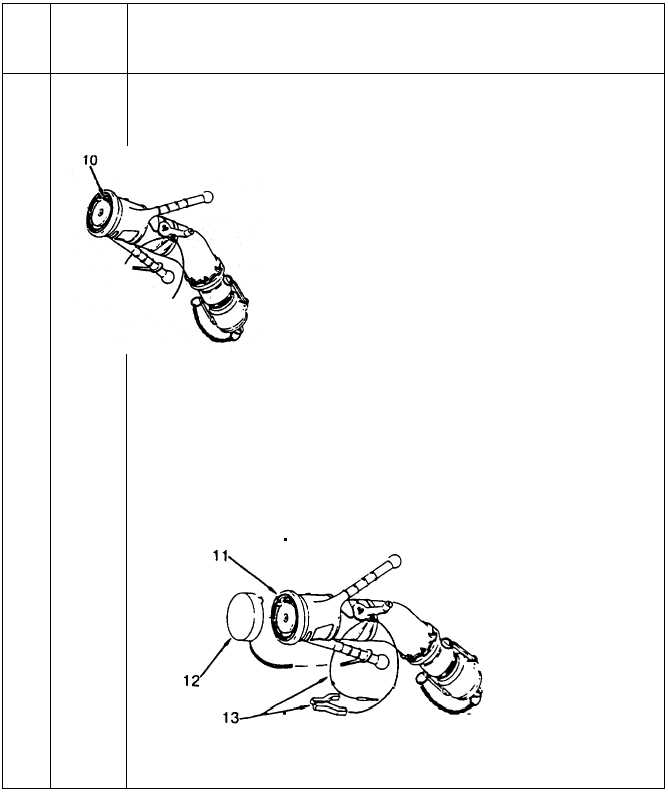

10

After

Indexing and Lock

Inspect discharge end of

Damaged or missing pins.

Pins

nozzle to check the three

indexing and three lock pins

Lock pins fail to return to

are present and not damaged. the UP position

Inspect for bent, broken or

worn pins.

Visually check that lock pins

are in the UP position. If they

are not,

squeeze the handle grips and

push down on collar, while

observing the lock pins. The

lock pins should 'spring' into

cutouts and collar should not

turn.

11

After

Bumper Collar

Inspect for cuts, tears, or

deformity.

12

After

Dust Cover

Inspect cover for cracks, tears Cracked, torn, non-secured

and security. Cover should fit cover. Cover fails to stay on

snugly on discharge end of

nozzle.

nozzle.

13

After

Ground Cable

Inspect for frayed or broken

Frayed or broken wires.

Assembly

wires, bent, broken or

Bent, broken or distorted

distorted clip or plug.

clip or plug.

2-9

|