|

| |

TM 10-4320-351-14

Table 2-3. Operator's Preventive Maintenance Checks and Services for Pumping Assembly

Location

Procedure

Not Fully Mission

Item

Interval

Item to

Capable if:

No.

Check/

Service

9

Before

Emergency

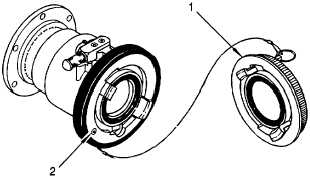

Remove dust cap (1), depress continuity ball (2) on valve seat,

Continuity ball does not

Shutoff

release and observe that ball pops back out. If ball does pop back

pop back out.

Valve

freely, electrically continuity is lost and static discharge is

possible. The coupling must be replaced. Notify unit maintenance.

10

Before

Accessory

Inspect for connector tightness, and cuts or breaks in cables

Cables are cut or

Module

broken, or connectors

Electrical

are loose.

Cables

11

Before

Accessory

Inspect ground cable for cuts, breaks or loose connections.

Cuts, breaks or loose

Module

connections make

Ground

ground cable unusable.

Cable

12

Before

Accessory

Inspect connector at battery for corrosion. Clean as required.

Connector is corroded.

Module

Battery

Cable

13

During

Pump-Engine

Inspect for leaks. Operation may continue with class I or class II

Any fuel leak or class

module

oil leaks.

III oil leaks are present.

2-10

|