|

| |

TM 10-4320-351-14

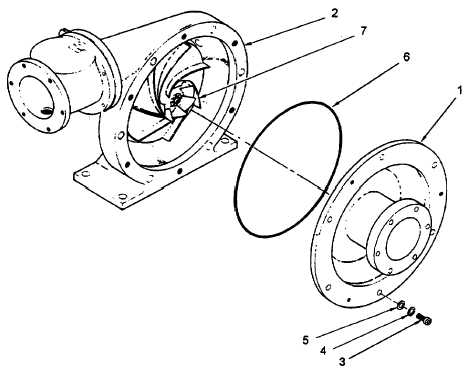

Figure 5-3. Fuel Transfer Pump Inlet O-Ring Replacement

WARNING

Dry cleaning solvent, P-D-680, Type III, is potentially dangerous to personnel and

property. Eye and skin protection is required. Avoid repeated and prolonged skin

contact. Wash hands immediately after exposure. Do not use near open flame or

excessive heat. Use only in areas with good ventilation. Rubber gloves should be

worn when handling fueling system components due to the toxic effects of some

fuel additives and the dry cleaning solvent.

(5)

Clean interior of pump housing with dry cleaning solvent SD (P-D-680), if required.

a.

Installation.

(1)

Lightly lubricate O-ring (6) with petrolatum and install in inlet O-ring groove. Do not allow the O-ring

to twist or roll during installation.

(2)

Install inlet in pump.

(a)

Install the inlet (1) by aligning the six retaining screw holes and the jack bolt holes with corresponding holes

in the housing body (2). Tap inlet lightly around circumference with rubber mallet or heel of palm to seat

inlet in housing. If inlet does not install easily, install the l/4-28 x 1 ½/2 in. jack bolts in the inlet and adjust

bolts until inlet is parallel to impeller housing, then back out jack bolts alternately 1/2 turn at a time until

mounting screws (3) can be started.

(b)

Lubricate with anti-seize compound and loosely install the six socket head screws (3), lock washers (4) and

flat washers (5) in the inlet (1). Tighten in a crossing pattern, one or two turns at a time, to fully seat the

inlet in the housing (2). When all six screws are snug, tighten alternately until secure.

5-8

|