|

| |

TM 10-4320-348-14

Table 4-1. Unit Preventive Maintenance Checks For Pumping Unit.

Location

Item

Item To

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

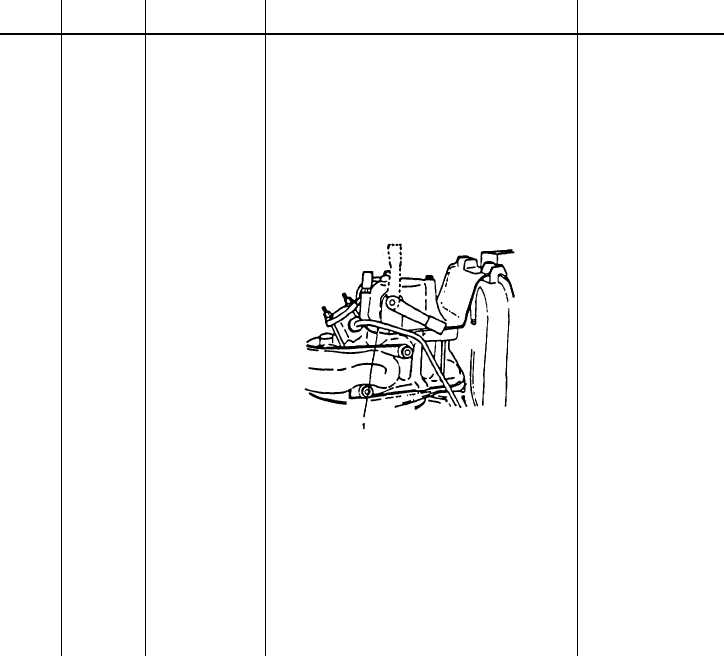

Add or drain oil until oil level is within the

Oil level is low.

operating range on dipstick (1).

Replace dipstick (1) all the way into oil pan

Dipstick is loose.

connection, then tighten the dipstick by

turning handle clockwise.

3

Semi-

Fuel Filter

The fuel filter must be replaced semiannually

Fuel cock is dirty.

annually

or after every 1000 hours of operation.

When filter is replaced, clean fuel cock at the

same time. For detailed procedure, refer to

paragraph 4-26.

4

Weekly

Fuel Injection

Check for leaks on fuel injection pipe (1) and

Fuel injection pipe leaks.

Pipe

fittings.

5

Semi-

Exhaust

WARNING

annually

Silencer

Exhaust system is very hot during

operation. Avoid contact with muffler

and related components during

checks described in this section.

Before touching portions of the

exhaust system, make sure that

equipment has cooled.

4-9

|