|

| |

TM 10-4320-343-14

6.6.4 Engine Maintenance.

(continued)

Start by tightening middle bearing cap and those on either

side, finish with bearing caps at ends. The crankshaft

must be able to rotate freely.

e . Install bearing caps (7) and (6), with their identification number

f .

9“

h .

corresponding to and in same direction as

that stamped on crankcase.

I n s t a l l

washers (5) and bolts (4).

Torque in accordance with appendix G.

I n s t a l l p i s t o n s ( 3 ) .

Install connecting rod caps (2) and connecting rod bolts (1). Torque in

accordance to appendix G.

Assembly flywheel assembly as follows:

(1) If ring gear (figure 6-9, 12) has been removed,

heat new ring gear to a

temperature of 248° F (120°C) and position

it on flywheel (11) and tap it

into position so it seats against shoulder.

(2) Install flywheel (11) with bolts (10). Torque in accordance with

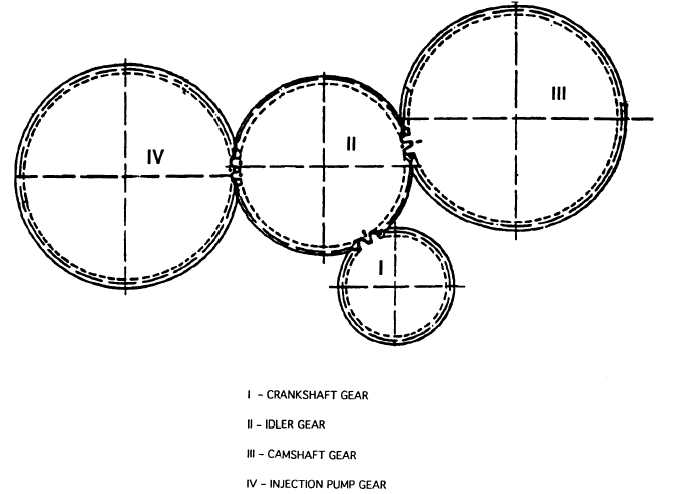

Figure 6-15. Timing Gears Layout with Match Marks

6-31

NOTE

appendix G.

|