|

| |

TM 10-4320-343-14

6.6.4 Engine Maintenance.

(continued)

(4)

(5)

(6)

(7)

(8)

(9)

( l o )

Withdraw centering finger and slide tool holder (4) out to diameter of

cylinder seating face.

Do not turn spindle counterclockwise when reworking

surface.

Adjust feed carefully.

A full turn (360°) of

knurled nut feeds tool hollder 1 inch (1.5 mm). failure to

obey this caution may result in equipment damage.

By means of knurled nut (5),

turn spindle (6) of turning device clockwise

and adjust tool holder (4) to face to be reworked.

Move tool holder (4) towards middle of bore.

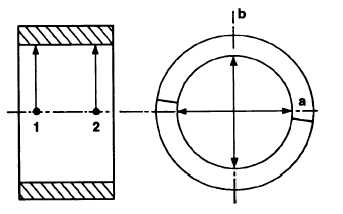

Using knurled nut (5) set tool over and slightly beyond distance "a" to

permit satisfactory refacing as shown in figure 6-13.

Selected cutting depth should not execeed inch (0.2mm).

Tighten setscrew (7) and turn spindle (6) to rework seating area until

smooth and/or flush with top of crankcase surface.

Set back tool holder and remove turning device.

Clean crankcase thoroughly.

Figure 6-14.

Checking Pre-loading of Engine Bearing Bores.

6-29

N O T E

This feed corresponds to 1/8th turn (45°) of knurled nut.

|