|

| |

TM 10-4320-342-24

4-2.

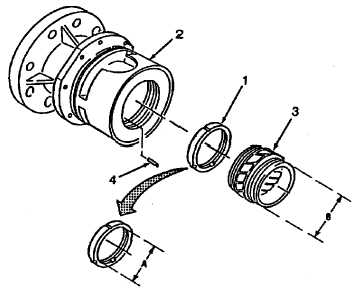

SUCTION MANIFOLD ASSEMBLY REPAIR.

CAUTION

When machining out the bronze wear ring, do not machine into suction manifold or

damage will occur.

(2)

Machine out the bronze wear ring (1) from the suction manifold (2).

c. REPAIR.

Repair is limited to replacement of damaged or defective components.

d. ASSEMBLY.

(1)

Cool the new bronze wear ring (1) in liquid nitrogen and install it in suction manifold (2).

(2)

Install setscrews (3) in suction manifold (2).

NOTES

· Machine bronze wear ring to 2.625/2.627 inch on the 200 GPM suction manifold,

P/N 43865.

· Machine bronze wear ring to 3.812/3.814 inch on the 600 GPM suction manifold,

P/N 4399-1.

(3)

When suction manifold (2) and bronze wear ring (1) has warmed to ambient temperature, finish machining inside

diameter of bronze wear ring.

Figure 4-1. Suction Manifold Assembly Repair

4-3

|