|

| |

TM 10-4320-324-14

c.

Repair. Use the following procedure to replace

valve seats and valve guides.

NOTE

Mandrels come in two sizes; one to fit exhaust valve

seat and the other to fit intake valve seat.

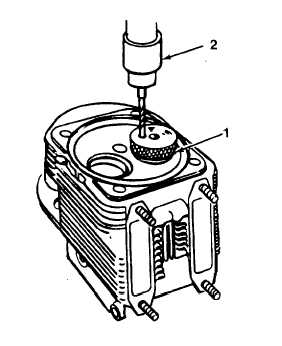

(1) Place mandrel (1) on valve seat and insert

guide through mandrel into valve stem.

Tighten guide so that mandrel is firmly in

place.

CAUTION

Do not drill into cylinder head.

(2) Insert drill (2) into mandrel (1) and drill through

valve seat at two positions 180 degrees apart.

(3) Remove guide and mandrel.

(4) Carefully remove drilled seat.

(5) Measure diameter of valve seat bore in cylinder

head.

NOTE

Intake valve seats have larger outside diameter than exhaust val ve seats.

(6) Measure outside diameter of new valve seat. Subtract the diameter of bore from diameter of seat. Difference

must not be less than 0.003 inch (0.076 mm).

(7) If needed repeat steps (1) through (6) for remaining valve seat.

CAUTION

Heating cylinder head for longer than 30 minutes or at a higher temperature than 430 F (220C) may cause head

to warp.

(8) Heat cylinder head in oven uniformly to a temperature of 430° F (220°C). Do not heat for more than 30 minutes.

6-39

|