|

| |

TM 10-4320-324-14

2-6. Initial Adjustments and Daily Checks.

a.

Perform all daily PMCS procedures.

b.

Make sure fuel tank is full before starting to pump site.

2-7. Operating Procedures.

a.

Startup.

CAUTION

Never operate pump unless pump housing is filled with liquid. The pump will not pump when dry.

Extended operation of a dry pump will destroy the seal assembly.

(1)

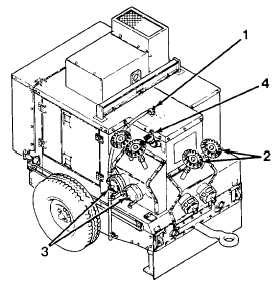

Open vent valve (1) a nd ensure that all suction valves (2), and discharge valves (3) are closed.

(2)

Check pump fluid level by carefully opening camlock levers on priming port cap (4) and raising port cap slightly

to see if liquid is discharged from priming port. If liquid is discharged, quickly install priming port cap and place

cam-lock levers in locked position. If fluid is not discharged, remove port cap and add clean liquid of the type to

be pumped, until the liquid level reaches the top of the priming port.

WARNING

Failure to replace priming port cap and lock securely will result in a two inch (5.08 cm) stream of liquid at

high pressure. Keep hands and face away or personal injury may result.

(3)

Install priming port cap (4) and place camlock levers in locked position.

2-12

|