|

| |

TM 10-4320-307-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Services - (Cont)

Item

Location

Not Fully

No.

Interval

Item to

Procedure

Mission Capable

Check/Service

if:

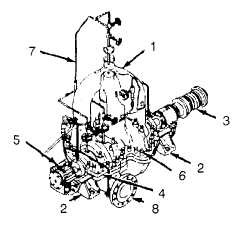

43

After

Pump As-

Check that pump assembly (1) is securely mounted to skid (2) Pump assembly

sembly

and flexible coupling (3).

or bearing hous-

Check that pump body (4) and mechanical seal housings (5)

ing mounting

are securely fastened together.

hardware is loose

or broken. There

Check that all nuts and lockwashers (6) are tight and free of

is evidence of

damage and corrosion.

Category Class III

Check piping assembly (7) for cracks and secure attachment

leaks or there are

to pump.

cracks.

Check pump body (4) for cracks at mounting feet (2).

Check suction and discharge flanges (8) for cracks and distortion.

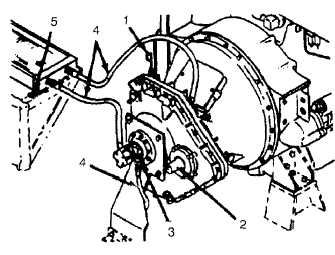

44

After

Speed In-

Check oil level using dipstick (1).

Low oil indication.

creaser

Check oil seal (2), pump gasket (3), and hoses (4) for signs of Loose or

leakage.

damaged.

components.

Check heat exchanger for secure attachment (5) and signs of

leakage.

Class III leakage.

2-39

|