|

| |

TM 10-4320-307-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Services - (Cont)

Item

Location

Not Fully

No.

Interval

Item to

Procedure

Mission Capable

Check/Service

if:

38

During

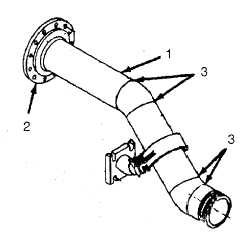

Suction and

Check for fluid leaks or cracks in flanges (2).

Category Class

Discharge

Check for cracked welds (3).

III fluid leaks or

Pipe

cracks are

Adapters (1)

Check for loose or missing hardware.

present.

39

After

3-Way Se-

WARNING

Category Class

lector Valve

Death or serious injury could occur if diesel fuel

III fuel leaks or

and Fuel

is not handled carefully. Use in a well-ventilated

fire hazard leak-

Line Assem-

area away from open flame, arcing equipment,

age are found.

bly

ignition sources, heaters, or excessive heat. Be

certain that fuel lines and connections are secure. Do not

inhale vapor. Do not overfill fuel tank. Engine must be

turned off and cooled be- fore refueling. Use proper

refueling procedures and equipment to avoid spillage. Do

not run engine near open fuel containers. DO NOT SMOKE.

CAUTION

Both supply and return 3-way fuel valves must be aligned

to the same selected fuel supply (auxiliary or unit tank).

Alignment to different supplies could cause engine

overheating, shut- down from rapid fuel exhaustion, or

fuel system overflow and the associated fire hazards.

2-35

|