|

| |

TM 10-4320-307-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Services (Cont)

Item

Location

Not Fully

No.

Interval

Item to

Procedure

Mission Capable

Check/Service

if:

35

During

Pump

While unit is operating, listen to the

Equipment dam-

Assembly

pump assembly components.

age is indicated

by continuous,

Excessive noise in the pump body

excessive noise

may indicate impeller binding or

There is

misalignment. A banging noise in the

evidence

pump body may be impeller cavitation.

Category

This is corrected by reducing engine

Class III leaks.

speed; check that the suction gate

valve is fully open. If cavitation

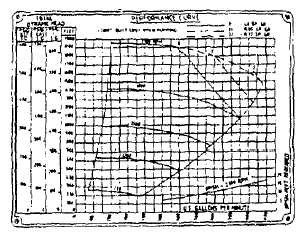

occurs, consult the performance data

plate for proper engine speed for the

specific gravity liquid being pumped.

Excessive vibration may be caused

by flexible coupling misalignment.

Inspect all pumping assembly fittings

and flanges for leakage.

2-33

|