|

| |

TM 10-3835-231-13

Table 2-1. Operator Preventive Maintenance Checks and Services for Tactical Petroleum Terminal- continued

Location

Item

Interval

Item to Check/Service

Procedure

Not Fully Mission Capable if:

No.

21

Before

Water Detection Kit

a. Inspect couplings for cracks and

Coupling damaged. Gaskets

Adapter Assembly

bent or broken locking arms.

damaged or missing.

Inspect for cut, torn or missing

couplings gaskets. Check for

missing dust caps and plugs.

b. Check that probe assembly is in

Probe assembly missing or

place and in good condition.

damaged.

22

Before

Female Coupling

Inspect couplings for cracks and

Coupling damaged. Gaskets

Adapter Assy

bent or broken locking arms.

damaged or missing.

Inspect for cut, torn or missing

couplings gaskets.

23

Before

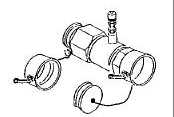

Y Assemblies

a. Inspect Y fittings for cracks,

Y cracked or severely corroded.

breaks and severe corrosion.

b. Inspect couplings for cracks and

Coupling damaged. Gasket

bent or broken locking arms.

damaged or missing.

Inspect for cut, torn or missing

coupling gaskets. Check for

missing dust caps and plugs.

c.

Inspect for leaks at couplings

Y assembly leaks.

and flange gaskets.

2-20

|