|

| |

TM 10-3835-231-13

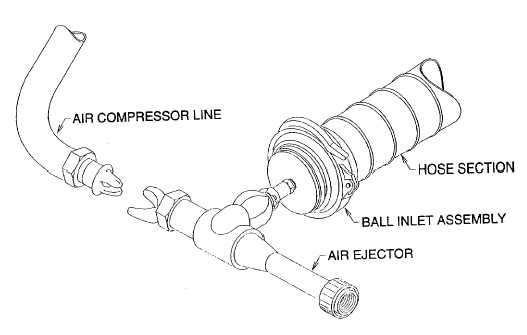

Figure 4-31. Evacuation Process View 4

WARNING

Be very cautious when evacuating fuel vapors. Fuel vapor and air are an explosive

mixture.

5

Put the compressor hose on the inlet side of the ejector. Start the air compressor and inject

compressed air into the ejector. This creates a vacuum and draws any remaining fuel vapor and

air from the hoseline and expels it from the exhaust end of the ejector assembly.

6

Operate the ejector about 10 minutes for each 1,000 feet of hose. When the hose flattens to a

ribbon like form, stop the air compressor, fold back the end of the hose and tie securely.

7

Remove the ball inlet assembly and air ejector.

8

Install the end cap on the collapsed hoseline to prevent hose from expanding before it is packed

into the flaking box.

9

When a hoseline length has been evacuated, collapsed, and capped, it is ready for packing.

(g)

Four-inch hoselines are to be drained, flushed with water, dried, capped, and transported to the

inspection and packing area. The displacement and evacuation kit normally furnished with the 4-inch

hoseline outfit (TO&E) can be used for this purpose.

(h)

Hoselines smaller than 4-inch must be drained, flushed, and dried without the benefit of a

displacement and evacuation kit.

(6)

Aluminum Fittings. Aluminum fittings (tees, elbows, nipples, adapters, etc.) are to be swabbed clean and

dry. Fittings should be tagged at the time of removal to aid identification during repacking. Box fittings and

transported to the final inspection and packing area.

4-81

|