|

| |

T M 1 0 - 3 8 3 5 - 2 1 9 - 14

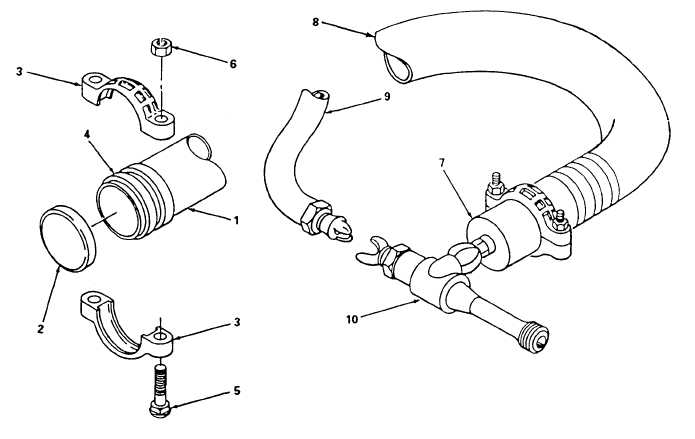

c. Air and Vapor Evacuation . (figure 2-11) After removal of residual fuel from hoseline, any air and fuel vapors

must be evacuated so that hose can be folded flat in flaking box.

W A R N I NG

(1)

(2)

(3)

(4)

(5)

(6)

Do not smoke, carry an open flame, or use any heat-producing device near

hoseline during fuel displacement and vapor evacuation operations. Hearing and

eye protection must be worn.

Breakdown hoseline into 1000-foot (300m) sections by disconnecting leading and trailing couplings.

Seal of the trailing end of first hose section (1) with a pipe cap (2), clamp (3), and gasket (4) and secure

with bolts (5) and nuts (6).

Ball inlet (7) should still be attached to leading end of first hose section (8) with air compressor line (9)

attached. Disconnect air compressor line (9) and attach ejector jet assembly (10) to ball inlet (7).

Connect compressor line (9) to ejector jet assembly (10).

Apply air pressure to ejector jet assembly (10). The rapid passage of air through ejector will create a

partial vacuum in the hoseline. It is necessary to operate compressor for approximately 10 minutes to

clear each 1000 feet (300m) of hoseline.

When hose has flattened apply hose clamp, shut off air compressor and remove ball inlet (7) from hose.

Install pipe cap (2) and secure with pipe coupling clamp then remove hose clamp.

Figure 2-11. Air and Vapor Evacuation.

2 - 3 5

|