|

| |

T M 1 0 - 3 8 3 5 - 2 1 9 - 14

2 - 8 . R o a d w a y C r o s s i n g G u a r d I n s t a l l a t i o n .

a. General. If hoseline must be laid across a roadway or railroad, hose should be laid under an existing bridge

or through an existing culvert. Hose may be pulled through culvert using a rope or steel fish tape with hose end

covered to prevent contamination. If no bridge or culvert is available, expedient roadway crossings maybe

constructed using roadway crossing guard. Hoseline must never be buried unprotected because weight of fill

would collapse hose, and any sharp rocks in contact with hose would cause a puncture. A plank should be nailed

to bottom of guard for greater hose protection. Do not lay hose directly in trench or railbed because shifting gravel

will gradually damage hose. If it is necessary to lay hose under a railroad bed, dig a tunnel beneath gravel of railbed

and nail a plank to bottom of guard.

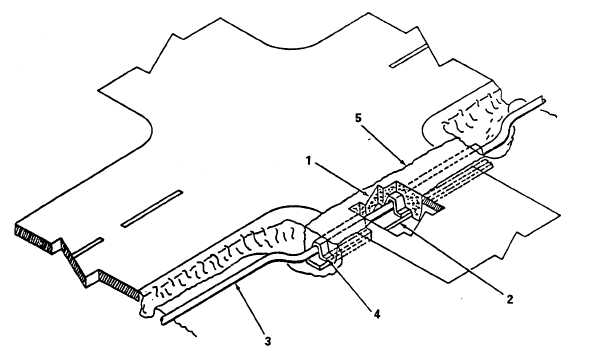

b. Installing Roadway Crossing Gua rd. (figure 2-7) Install roadway guard as follows:

(1)

(2)

(3)

(4)

(5)

Dig a trench (1) 12 inches (304.8 mm) deep across road or railbed.

C A U T I ON

Remove stones and sharp rocks from trench before laying hoseline. Rocks can

cause hoseline damage and failure.

If hoseline is being run beneath a railroad bed, a plank (2) must be placed in trench before laying in

hoseline (3). Planking may also be used in roadway crossings.

Lay hoseline (3) in trench (1).

Place roadway crossing guard (4) in position. Nail guard to plank (2), if used.

Backfill trench (5) using dirt removed in step a. Do not put any stones on top of crossing guard (4). Fill

trench (1) to a level 1 to 2 inches (25.4-50.8 mm) above original roadbed before packing.

Figure 2-7. Installing Roadway Crossing Guard.

2 - 2 5

|