|

| |

TM 9-2330-398-24

4-1.

ENGINE ASSEMBLY REPAIR (continued).

21.

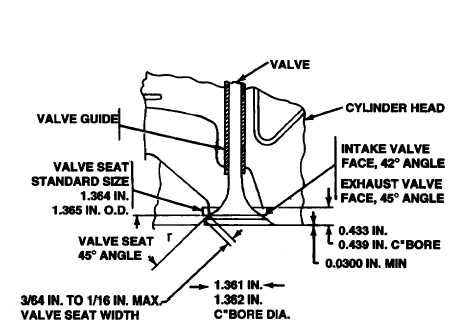

Repair valves that can be refaced by grinding to the requirements shown in Table 4-1.

22.

Inspect valve seats. Reface valve seats if seat face is slightly pitted, burned, or worn and can be refaced to the

requirements in Table 4-1. If valve seats are loose, they must be replaced.

23.

Inspect valve spring for evidence of damage. Replace spring if cracked, pitted, or if ends are out of square.

24.

Check valve spring for 1.875 inches (4.76 cm) free length.

25.

Inspect valve spring under load conditions using a compression scale as follows:

a.

Compress spring to 1.528 inches (3.88 cm) (valve closed), and check

scale for 45 to 49 pounds (20 to 22 kg) compression.

b.

Compress spring to 1.182 inches (3.00 cm) (valve open), and check

scale for 87 to 97 pounds (39 to 44 kg) compression.

c.

Discard any spring that fails to meet the above requirements.

4-15

|