|

| |

TM 9-2330-398-24

3-20. FUEL METERING PUMP REPLACEMENT (continued).

NOTE

Position of No. 1 piston can be checked by removing timing hole screw on left side of pump

mounting flange and inserting a 1/8-inch diameter brass wire in timing index hole. If piston is on

compression stroke, wire will enter index hole in gear face. If approximate depth of wire is 1 1/8

inches, piston is on compression stroke. If depth is 7/8 inch or less, rotate flywheel one complete

revolution and insert wire again.

2.

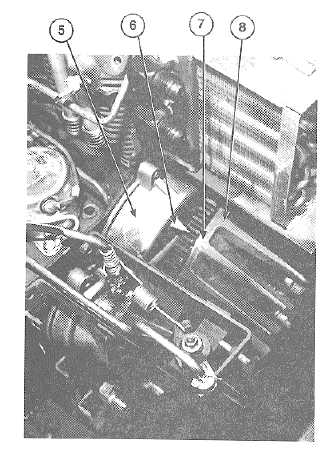

Position No. 1 piston on compression stroke by placing port closing (PC) mark (7) on flywheel (8) in line with

timing mark (6) on gearcase cover (5).

NOTE

• Be careful to retain shims between crankcase and fuel metering pump.

• The correct thickness of shims is stamped on crankcase above fuel metering pump.

3.

Remove four nuts (11), lockwashers (10), and washers (9), preformed packing (12), and fuel metering pump (1)

from crankcase (13). Discard lockwashers and preformed packing.

3-59

|