|

| |

TM 9-2330-398-24

2-55. SAFETY RELIEF VALVE REPLACEMENT (continued).

NOTE

Air supply can be either a prime mover or a stationary source.

2.

Attach air supply line to valve end of test gage.

3.

Pressurize system and close valve on test gage when system is full.

4.

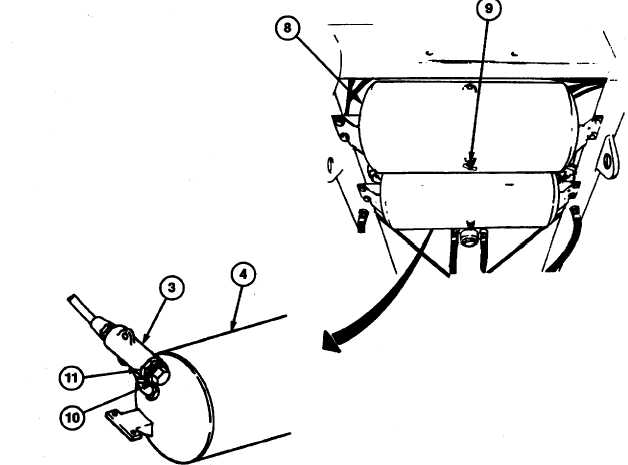

Note gage reading and drain secondary (forward) air reservoir (8) by opening drain valve (9) on bottom of reservoir

(8). When all air has been exhausted from secondary system, gage should read 75 psi (517 kPa). If pressure is

not correct, do step 5.

5.

Loosen locknut (11) at base of cap (10) on valve (3) and turn cap (10) clockwise to increase pressure setting,

counterclockwise to decrease pressure setting.

6.

Repeat step 5 until desired pressure is obtained, then tighten locknut (11).

7.

Remove air system test gage from semitrailer emergency gladhand.

FOLLOW-ON MAINTENANCE:

• Disconnect ground (refer to TM 9-2330-398-10).

2-139

|