|

| |

TM 55-2915-335-30&P

2-22. PUMP-END MOTOR BEARING - lNSPECT/REPLACE (Cont)

2-22

b.

c.

d.

e.

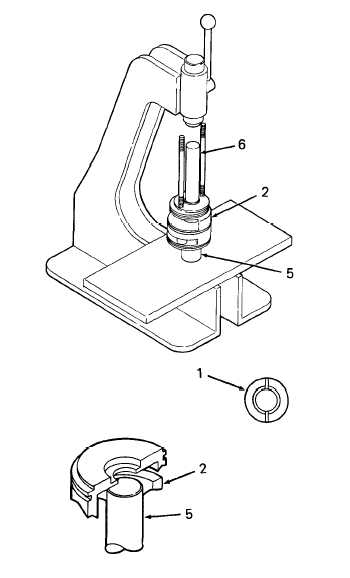

When pressing in the pump-end motor

bearing, the impeller housing must have

solid support just below the bearing seat,

Failure to support the housing as in-

structed may result in permanent damage

to the impeller housing.

Carefully insert round bar press fixture (5) into

housing inlet port. Place bar fixture against top

surface of impeller chamber. Do not attempt to

press bearing into impeller housing without sup-

port directly below bearing seat.

Stand impeller housing (2) and press fixture (5) on

arbor press, as shown. Center bearing (1) over seat

in housing. Slotted face of bearing must be up.

Center bearing installation tool (6) (Figure 1, Ap-

pendix D) in bearing.

Bring arbor down to meet installation tool (6).

Square-up top of installation tool with arbor.

Double check that bearing (1) is in line with seat.

Press bearing (1) into seat until it bottoms in

housing (2). Make sure bearing bottoms fully in

seat. Remove bearing installation tool and support

fixture.

GO TO NEXT PAGE

2-78

|