|

| |

TM 55-2915-335-30&P

2-21. PUMP COVER AND INLET SEAL- lNSPECT/REPAIR/REPLACE (Cont)

2-21

f.

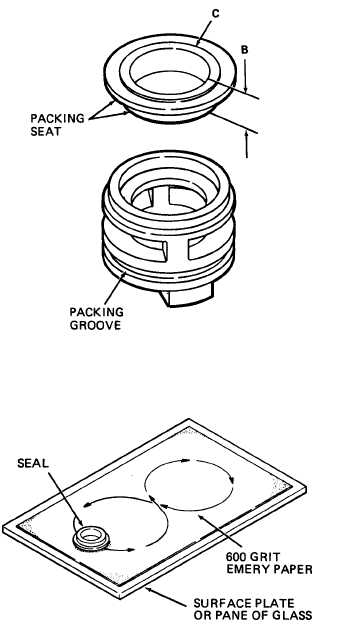

e. Use outside caliper to measure seal height, dimen-

sion B. If seal height is less that 0.201 inch, replace

seal.

Visually check condition of inlet seal seat surface

C. If wear grooves can be seen, or if surface looks

dull, lap seat per paragraph 3.

3. REPAIR INLET SEAL SEAT

a.

b.

c.

d.

e.

Place sheet of 600 grit, wet or dry emery paper on

inspection surface plate or pane of glass. Place seal

(6) on emery paper with seal seat down, as shown.

With light and even pressure, move seal in figure-8

path. Make only three or four passes.

Check seal surface condition. If necessary, make

three or four more passes and recheck seal sur-

face. Repeat lapping operation until grooves are

gone.

Wipe off surface plate with clean cloth and replace

emery paper with plain white bond paper. Repeat

figure-8 pattern on paper to polish seal surface to

a mirror finish.

Visually check seal surface condition. Surface must

reflect light evenly.

Measure seal height B per paragraph 2.e, INSPEC-

TION. If seal height is less than 0.201 inch, replace

seal.

GO TO NEXT PAGE

2-74

Change 1

|