|

| |

TM 55-2915-335-30&P

2-18. ARMATURE AND FIELD TUBE ASSEMBLY - lNSPECT/REPLACE (Cont)

2-18

4. INSPECTION

a. Inspect Armature

(1)

(2)

(3)

(4)

(5)

(6)

(7)

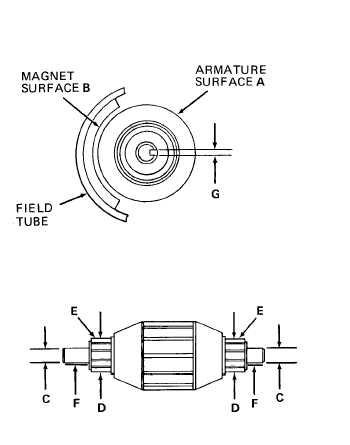

A bent armature shaft will cause armature to

rub on field tube magnets. Check for shiny

spots on armature surface A. Use a flashlight

to check for scoring or loss of material on

field tube magnet surfaces B. If signs of wear

between armature and field tube magnets are

found, replace both armature and field tube.

Using a caliper set, measure diameters C of

armature shaft journals. If either measure-

ment is less than 0.312 inch (7,92 mm) re-

place armature.

Using a caliper set, measure commutator

diameters D. If less than 0.700 inch (17,78

mm) replace armature.

Check roughness of commutator surfaces E.

Run your finger nail lightly over the surface

of each commutator bar. Commutator sur-

face should be smooth with no nicks or

scratches to catch your finger nail. Surface

can be polished to remove any defects by

using 600 grit emery paper moistened with a

light weight oil. After polishing wipe clean

with a lint free cloth moistened in cleaning

solvent (Item 7, Appendix C).

Check commutator surfaces E for pitting. If pitting can not be removed using 600 grit emery paper and

light oil, discard armature.

Shaft surface F should be smooth and free of any scratches and nicks. Polish with 600 grit emery paper and

a lightweight oil. Visually check surface with a light, and spin armature while gently holding the shaft be-

tween your finger tips. Shaft should feel smooth.

Inspect armature keyways if key-drive type is used. Measure keyway width G. Using a feeler gage, take

measurement at outside diameter of shaft. If width G is more than 0.067 inch (1,70 mm), replace both ar-

mature and impeller. The key slot width can also be checked using a No. 50 drill. If the shank of a No. 50

drill can be inserted into the keyway, the keyway is worn.

GO TO NEXT PAGE

2-59

|