|

|||

|

|

|||

|

Page Title:

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES |

|

||

| ||||||||||

|

|

TM 5-5430-226-12

(5) Procedures Column. This column tells you how to do the required checks or services. Carefully follow

these instructions. If you do not have the tools, or if the procedures tell you to, have unit maintenance do the work.

(6) Equipment Is Not Ready/Available If Column. This column tells you when and why your equipment

cannot be used.

NOTE

The terms ready/available and mission capable refer to the same status: equipment is on hand

and is able to perform its combat missions. (See DA PAM 738-750).

c. Leakage Definitions.

Class I

Seepage of fluid (as indicated by wetness or discoloration) not great enough to form drips.

Class II

Leakage of fluid great enough to form drops, but not enough to cause drops to drip from item

being checked/inspected.

Class III

Leakage of fluid great enough to form drops that fall from the item being checked/inspected.

2-4. OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES

CAUTION

Equipment operation is allowable with minor leakages (CLASS I or II). Of course, you must

consider the fluid capacity in the item/system being checked/inspected. When in doubt, notify

your supervisor.

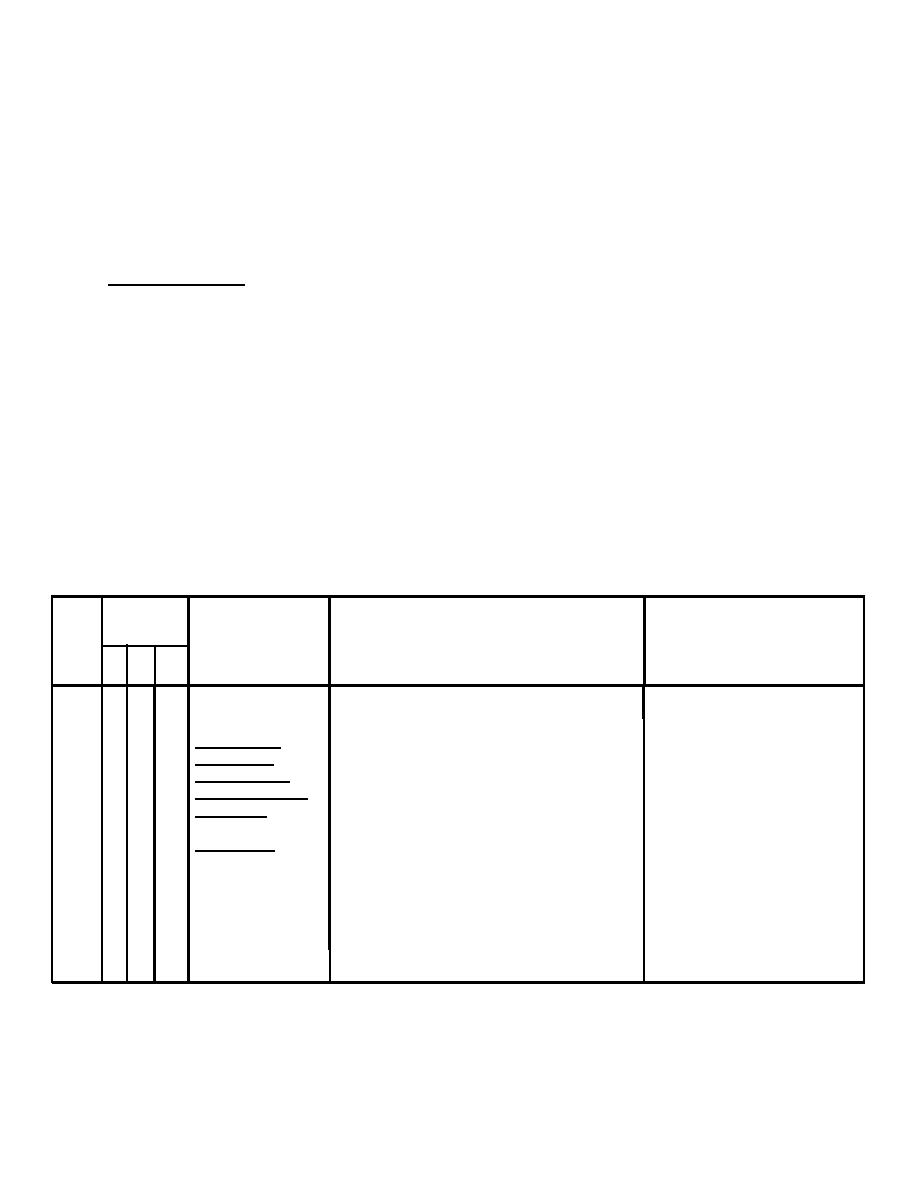

Table 2-1. Operator Preventive Maintenance Checks and Services.

B - Before Operation

D - During Operation

A - After Operation

INTERVAL

Procedures

Equipment is not

Item

Item To Be

Check for and have repaired

Ready/Available

No.

B

D

A

Inspected

or adjusted as necessary

If:

1

Tank, Fabric

Inspect entire unit for physical dam-

Major components are miss-

Collapsible,

age. Check that all major compo-

ing.

20,000 Gallon

nents are present.

or 50,000 Gallon

(End item)

2

Water Tank

a. Inspect tank for tears, punctures,

Tank is torn, punctured or

and loose seams.

seam(s) is loose.

b. Inspect for loose or missing bolts

Bolts are missing.

where fittings connect to tank.

Tighten loose bolts.

c. Inspect for damaged or missing

Dust cover missing.

dust covers. Check covers for dam-

aged or missing gasket.

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |