|

| |

TM 5-4320-308-13

Table 3-2. Unit Maintenance Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 2.

Shut down engine. With engine level, check oil level (para 3-1.).

Add oil if necessary.

Step 3.

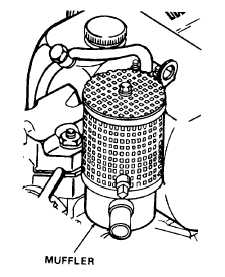

Check muffler for obstruction.

Remove obstruction.

Step 4.

Notify intermediate maintenance.

6.

PUMP MAKES EXCESSIVE NOISE

Step 1.

Check volute for foreign material.

With engine stopped and suction hose removed, inspect interior of suction (intake) flange for foreign

material or obstruction.

CAUTION

Excessive pump noise can indicate that pump is running dry. This condition can cause serious

pump damage.

Step 2.

Check that suction hose is immersed in fuel or properly connected to container from which fuel is

being pumped. Fuel level in container shall be above suction hose connection.

Relocate suction hose connection below surface of fuel.

3-28

|