|

| |

TM 5-4320-306-24

4-12.

REPLACE/REPAIR CRANKSHAFT ASSEMBLY (Continued)

For both of these out-of-round conditions, also check connecting rods, pistons, cylinder, and main bearing

bushings for unusual wear Journal width measured at point 3 should be 1.4173 to 1.4189 inches (36.0 to

36.039 mm) Fillet radius measurement should be 0.1693 to 0.1772 inch (4.30 to 4.50 mm). If either

measurement is outside specified limits, the crankshaft must be replaced

8

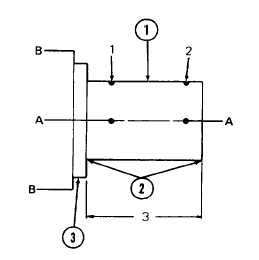

Inspect crankshaft center bearing journal

a.

Measure diameter of crankshaft center bearing journal

(1) at points 1 and 2 and along axes A and B with

micrometer. Measure width of journal at point 3.

Measure radius of fillets (2) between center bearing

journal and crank cheeks (3).

b.

Nominal center bearing journal diameter should be

2.8728 to 2.8736 inches (72.97 to 72.99 mm). If any

measurement is outside the specified limits, the

crankshaft must be replaced. However, if journal is

evenly worn, not out-of-round, and main bearing journal

and crankpin diameters are within their specified limits,

only center main bearings need be replaced.

c

Replace main bearings in accordance with paragraph 4-

13. Make sure that main bearing radial clearance does

not exceed 0.0020 to 0 0118 inch (0 052 to 0 3 mm). If

specified limits are exceeded, the crankshaft must be

replaced.

d.

If measurements at points 1 and 2 differ by more than 0.0028 inch (0.07 mm) and/or one set is outside the

specified limits, the journal is worn into a conical shape and crankshaft must be replaced. If measurements

along axes A and B differ by more than 0.0028 inch (0.07 mm) and/or one set is outside the specified

limits, the journal is worn into an oval shape and crankshaft must be replaced. For both these out-of-round

conditions, also check connecting rods, pistons, cylinders, main bearing bushes, and main bearings for

unusual wear. Journal width measured at point 3 should be 1.4576 to 1.4577 inches (37.0 to 37.025 mm).

Fillet radius measurement should be 0.1693 to 0.1772 inch (4.30 to 4.50 mm). If either measurement is

outside specified limits, the crankshaft must be replaced.

REPAIR:

1

Inspect crankshaft drive end (to flywheel) contact surface. Lightly stone surface with surfacing stone to remove

any fretting or brinnelling Remove dirt and debris from contact surface.

WARNING

Death or serious injury could occur if diesel fuel oil is not handled carefully. Use in a well-

ventilated area away from open flame, arcing equipment, ignition sources, heaters, or excessive

heat. Always store fuel in proper, marked containers. DO NOT SMOKE.

2

If crankpins and bearing journals are only slightly outside specified limits because of nicks, burrs, or high spots,

remove these slight imperfections with crocus cloth wet with diesel fuel oil. Work wet crocus.

4-98

|