|

| |

TM 5-4320-306-24

4-7. REPLACE/REPAIR VALVES, VALVE GUIDES, AND VALVE SEATS (Continued)

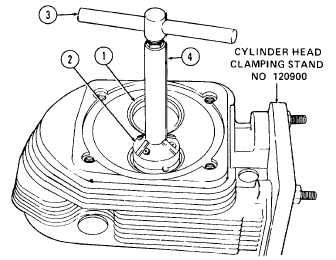

g. Inspect installed valve seat insert rings (1) for nicks,

burrs, or other minor damage to valve mating

surfaces. Very carefully smooth out any nicks, burrs,

or other minor damage with valve guide mandrel No

122305, valve seat ring cutter No. 122302 (2),

mandrel handle 122306 (3), and holder No 122304

(4).

h. Check valve head/cylinder head seat clearance with NEW valve in accordance with procedure in

CLEANING/INSPECTION step 10.

Maximum clearance is 0 2520 inch (6.4 mm)

Minimum clearance is 0.2283 inch (5.8 mm)

i. If maximum clearance is exceeded, replace valve seat insert rings again Follow procedure described in step d. If

clearance is below minimum, remachine valve seat insert rings with valve seat ring cutter No. 122302 and holder

No 122304 Reconfirm that clearance falls within limits after remachining.

NOTE

If remachining will cause either limit to be exceeded, replace valve seat insert

rings or valves, respectively.

WARNING

Death or serious injury could occur if diesel fuel oil is not handled carefully. Use

in a well-ventilated area away from open flame, arcing equipment, ignition

sources, heaters, or excessive heat. Always store fuel in proper, marked

containers. DO NOT SMOKE.

Death or serious injury could occur if compressed air is directed against the skin.

Do not use compressed air for cleaning or drying unless the pressure is/has been

reduced to 30 psi (2.11 kgcm2) or less. When working with compressed air always

use chip guards, eye protection, and other personal protective equipment.

j. Clean valve seat insert rings with diesel fuel oil and dry with low pressure compressed air

4-54

|