|

| |

TM 5-4320-306-24

4-6. REPAIR CYLINDER HEAD ASSEMBLY AND ROCKER ARMS (Continued)

CLEANING/INSPECTION:

WARNING

Death or serious injury could occur if diesel fuel oil is not handled carefully. Use in a well-

ventilated area away from open flame, arcing equipment, ignition sources, heaters, or excessive

heat. Always store fuel in proper, marked containers. DO NOT SMOKE.

Death or serious injury could occur if compressed air is directed against the skin. Do not use

compressed air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11

kgcm2 ) or less. When working with compressed air always use chip guards, eye protection, and

other personal protective equipment.

1

Mount cylinder head (1) on cylinder head clamping stand No. 120900 and clamping plate No. 120910 Clean with a

clean cloth dampened with diesel fuel oil. Use wire brush where necessary Dry with compressed air.

2

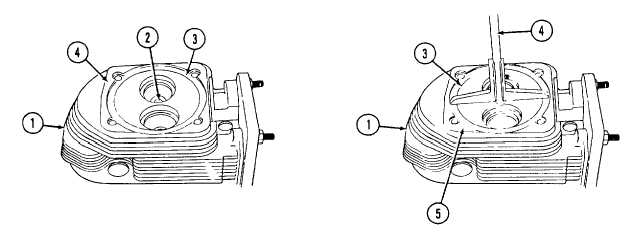

Inspect cylinder head (1) for cracks, rust, corrosion, and excessive heat damage. Inspect for accumulated carbon

around injector spray tips (2). Replace cylinder head if it is damaged

3

Check that cylinder head seat (3) is smooth and flat If not, use a depth gage (4) to measure distance from the

cylinder head bottom (5) to cylinder head seat (3) or sealing surface. If the cylinder head bottom-to-cylinder head

seat distance is between 0.2283 inch (5.8 mm) and 0.2480 inch (6.3 mm), the cylinder head seat can be smoothed

and flattened by remachining. If distance is not within the specified limits, replace cylinder head (1).

4-41

|